-

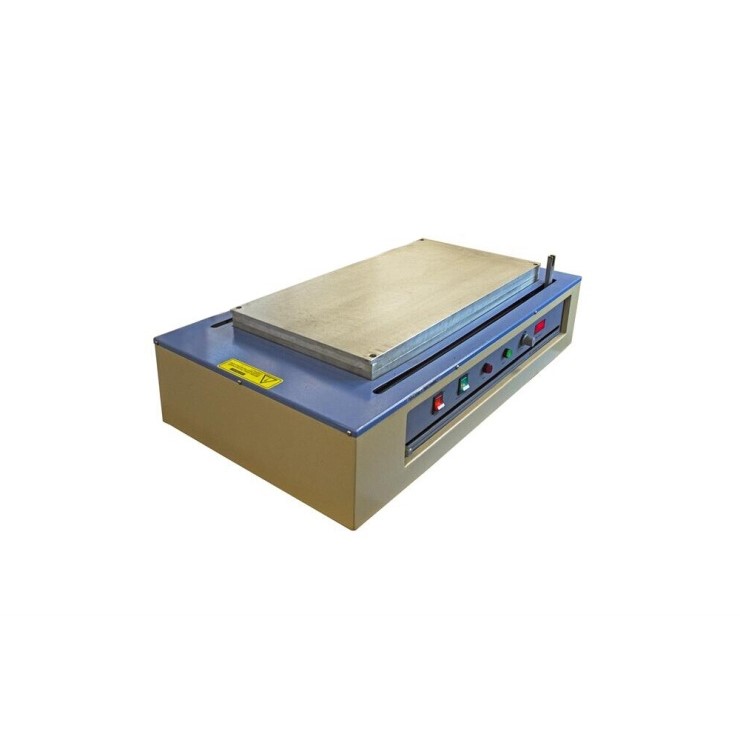

Large Tape Casting Flim Coater With Heatable Vacuum Bed

MSK-AFA-L1000 Compact Coater with automatic drying function is mainly used for coating liquid or colloidal film in laboratory. The equipment adopts the bottom vacuum to absorb the samples, and has bottom heating function. The heating temperature can reach up to 120℃, and the function of film baking is realized during the coating process, so that the film can be dried quickly.

Send Email Details -

High Vacuum Plasma-enhanced Chemical Vapor Deposition System (PECVD)

Parallel-plate Capacitive PECVD is a technology that uses plasma to activate reactive gases to promote chemical reactions on the substrate surface or near-surface space to form solid-state films. The basic principle of plasma chemical vapor deposition technology is that under the action of high frequency or DC electric field, the source gas is ionized to form plasma, and the low temperature plasma is used as the energy source, an appropriate amount of reactive gas is introduced, and the plasma discharge is used to activate the reactive gas and forms chemical vapor deposition.

Send Email Details -

Bench-Top NanoFiber Electrospinning System

Electrospinning is a simple and effective process, with the action of a high-voltage electric field, for spinning polymer solutions or melts into fine fibers with dimensions ranging from micrometers to nanometers, namely polymer jet electrospinning.

Send Email Details

It can be used for preparation of biopolymers, commodity polymers, and prepolymer nanofibers; preparation of polymer blend nanofibers; preparation of surfaces or films with nanopores, nanoparticles, and nanobeads. -

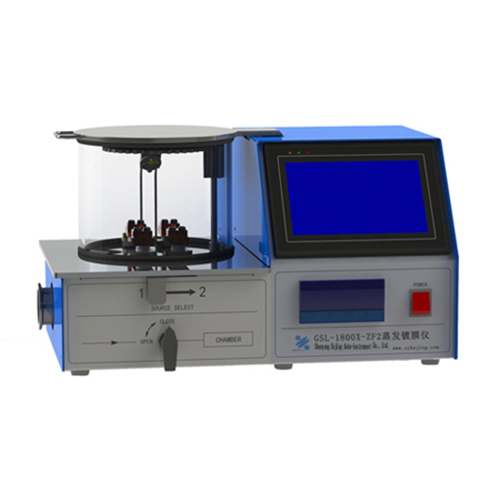

Vacuum Thermal Evaporation Coater With Two Heating Sources

GSL-1800X-ZF2 Evaporation Coater can be rotated during the evaporation coating process, so that the evaporated film material is evenly distributed on sample surface. The machine is equipped with two groups of evaporation units, one W-boat and one tungsten wire basket.

Send Email Details -

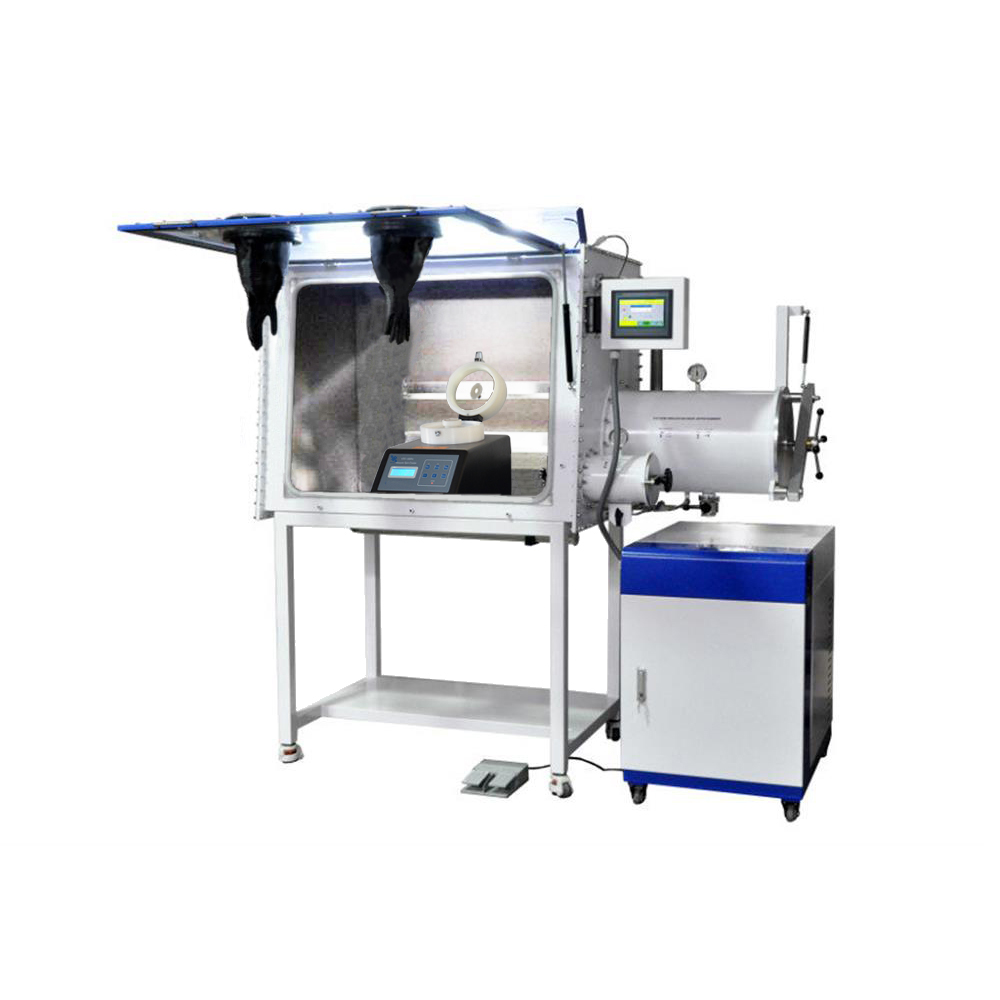

Hi-Speed Spin Coater (10K rpm And 5" Max) Use In Glove-box

VTC-100PA-DC Vacuum Spin Coater is equipped with 3 vacuum chucks (for standard) of different sizes, and different vacuum chucks can be selected according to the size of samples. During working, VTC-100-DC vacuum spin coater uses vacuum plate adsorption method to fix the sample onto the sample plate. The equipment uses two-stage program to control the speed.

Send Email Details -

Large Tape Casting Flim Coater With Coating Area 1100mm×550mm

MSK-AFA-L1100 Automatic Coater is widely used in various high-temperature coating research, such as ceramic films, crystal films, battery material films, special nano films. The length of the film can be controlled according to the travel distance of the doctor blade, whose limit is up to 1025mm. Related drying equipment can be added to this machine according to customer requirements to meet more needs for coating.

Send Email Details -

Plasma Sputtering Coater With 3 Sputtering Sources

VTC-600-3HD Threel-Head Magnetron Sputtering Coater is a coating equipment newly developed by our company, and is used to prepare single-layer or multi-layer ferroelectric film, conductive film, alloy film, semiconductor film, ceramic films, dielectric film, optical film, oxide film, hard film, PTFE film, etc. VTC-600-3HD three-head magnetron sputtering coater is equipped with three target guns, one RF power supply for sputter coating of non-conductive materials, and two DC power supplies for sputter coating of conductive materials.

Send Email Details -

Ultrasonic Spray Pyrolysis Coater

MSK-USP-04C Ultrasonic Spray Pyrolysis Coater/Glue Sprayer uses a stepper motor and a microprocessor to control the volumetric pump to ensure accurate transmission of solutions through the infusion set and the continuity of ultrasonic spray process. An ultrasonic atomizer is used to prepare a thin micro-nano coating, and a stepper motor is used to control the atomizer to move in the X-axis and Y-axis directions, and the moving speed can be adjusted within a certain range to ensure the uniformity of coating on the substrate surface.

Send Email Details -

6 Position Nanometer Dip Coater With Speed 1-200 mm/min

PTL-OV6P 6-Position Dip Coater can pull and coat up to 6 samples under the same external conditions when working, and solution container can load different liquid coating materials. The pulling time, dipping time and drying time of the sample can be set by program. After one coating, manually turn the charging beaker to make the sample enter the next coating process. This machine is equipped with a thermostatic oven.

Send Email Details