- Company News

- Industry News

- Video

- Cutting and Dicing Saw

-

Grinding and Polishing Machine

- Precision Grinding and Polishing Machine

- Automatic Pressure Grinding and Polishing Machine

- Automatic Metallographic Grinding and Polishing System

- Vibratory Polishing Machine

- Auxiliary Device for Grinding and Polishing

- Grinding and Polishing Machine Accessories

- Grinding and Polishing Machine Consumables

- Electrolytic Polishing and Etching Machine

- Film Coating Machine

- Melting System

- Plasma Cleaner

- Lab Mill and Mixer

- Lab Press

- Testing and Analysis Instruments

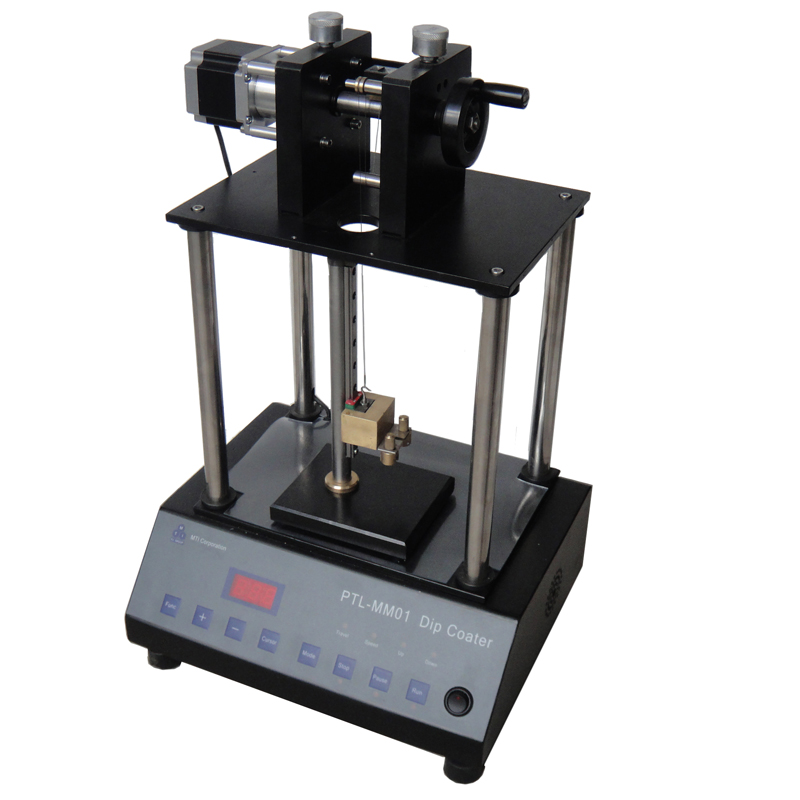

How to Use PTL-MM01 Programmable Dip Coater to Complete Work Efficiently?

Our Shenyang Kejing's PTL-MM01 programmable dip coater uses a self-developed high-precision single-chip control system, which can provide precise and stable control capabilities. The lifting speed and stroke of the equipment can be set according to needs, and it maintains smooth and accurate operation during operation. In addition, users can also adjust the lifting direction through manual buttons to achieve more flexible operation. So how can we make good use of the lifting coating machine to complete the work tasks more efficiently?

Accurately set the lifting parameters:

PTL-MM01 programmable dip coater supports precise setting of lifting speed and stroke. According to different experimental requirements, the appropriate speed range (1-200mm/min) and lifting stroke can be set. Scientific parameter setting can not only ensure the quality of the film, but also improve operational efficiency. It is recommended to find the lifting parameters suitable for specific materials and samples through multiple tests before the experiment to achieve the best film growth effect.

Optimize the operation process:

PTL-MM01 programmable dip coater has both manual control and automatic control functions, and users can flexibly switch according to experimental requirements. For example, the use of automatic control mode can achieve a fast dipping and pulling process, while manual control is suitable for experiments that require more detailed adjustments. Mastering the manual and automatic operation skills of the equipment can effectively improve the flexibility and efficiency of the operation.

Scientific cleaning and maintenance:

The cleaning and maintenance of the PTL-MM01 programmable dip coater are very important, especially when it is used frequently. The PTL-MM01 programmable dip coater is designed with easy operation and simple cleaning process in mind. Clean the equipment regularly, especially the sample fixture and pulling wire, so that the equipment is in the best working condition to avoid contamination and affect the uniformity of the film layer. In addition, regularly check the working condition of the power adapter and drive motor to ensure the normal operation of the system.

Through the above three methods, you can use the PTL-MM01 programmable dip coater more efficiently, improve experimental efficiency, and ensure the quality of the film. I hope this news can help people who are working with the PTL-MM01 programmable dip coater. We will update more related news in the future. If you are interested, you can pay more attention to our website!