- Home

- >

- Products

- >

- Vacuum Chuck

- >

Vacuum Chuck

1.The rotating vacuum chuck is a precision vacuum equipment for fixing thin sheet samples.

2.Through holes on the rotating vacuum chuck, air inside an enclosed space is extracted or thinned.

3.The pressure difference squeezes the sample and wafer vacuum chuck firmly together to adsorb and fix the sample.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 100 sets

- Information

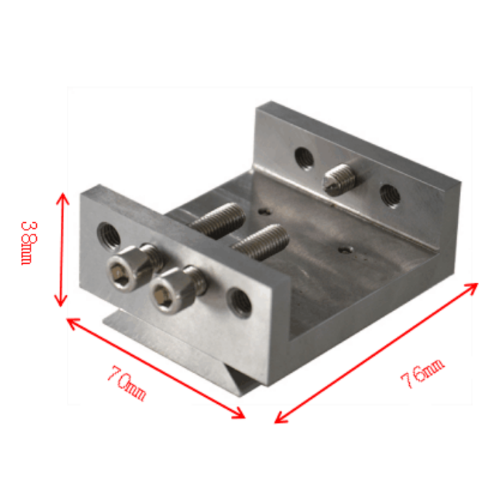

Introduction of circular vacuum chucks:

The wafer vacuum chuck is independently designed and developed by our company, and wafer vacuum chuck is a precision vacuum equipment for fixing thin sheet samples. There are certain holes on the vacuum chuck, through which air inside an enclosed space is extracted or thinned through a pneumatic pipeline or a vacuum device, so that the pressure difference between the inside and the outside squeezes the sample and the rotating vacuum chuck firmly together to adsorb and fix the sheet sample. The wafer vacuum chuck can be used together with SYJ-400 dicing saw manufactured by our company for cutting or adsorbing samples when slicing and grooving thin samples. Rotating vacuum chuck can also be used together with a vacuum spin coater for adsorbing and fixing flake samples to be coated.

Advantages of circular vacuum chucks:

1. The circular vacuum chucks produced by our company are designed for SYJ-400 dicing saws and can be seamlessly matched to ensure stable and precise adsorption of samples during slicing and grooving.

2. The holes of the wafer vacuum chuck are finely designed and designed for thin samples, so that the integrity of the samples and high-quality processing effects can be maintained during processing.

3. The rotating vacuum chuck can not only be used with the dicing saw, but also combined with the vacuum spin coater, which is suitable for a variety of process scenarios such as coating and precision cutting.

Repair and maintenance of circular vacuum chucks:

As a high-precision device, daily maintenance of vacuum chucks is very important. It is recommended that buyers regularly check the vacuum seals and pneumatic pipelines of the suction cups to ensure the stable operation of the equipment. If the adsorption force is found to be weakened, the patency of the suction cup holes should be checked in time, and the seals should be replaced in time. For suction cups used for a long time, professional maintenance and calibration are recommended to ensure that the equipment is always in the best working condition.

Logistics:

About us:

Our company can provide perfect after-sales service. If you encounter any problem after purchasing the product, we will do our best to solve your problem. We are working hard to become the first brand in the field of domestic material analysis equipment. The gap between us and foreign counterparts is narrowing. We believe that in the near future, the Kejing brand will also become a synonym for professionalism and outstanding cost-effectiveness in the international market. We will help you with better services.