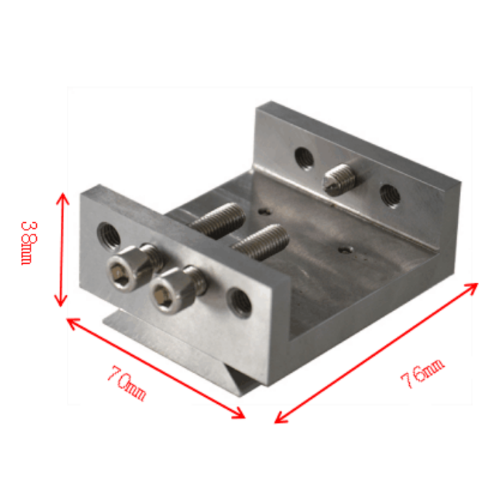

Microporous Vacuum Chuck

1. Vacuum chuck for fixing thin pieces is independently designed and developed by our company, ensuring the uniqueness and quality control of the product.

2. Vacuum chuck for fixing thin pieces is specially designed for fixing thin sheet samples, so that the samples are stable and do not shift during processing.

3. Vacuum chuck for fixing thin pieces is fixed by vacuum adsorption, reducing the risk of sample damage caused by uneven clamping force.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of vacuum chuck for dicing machine:

Vacuum chuck for dicing machine is a precision vacuum device designed and developed by our company for fixing thin sheet samples. There are certain holes on the suction cup, that is, through pneumatic pipelines or certain vacuum devices, the air in the thin and closed space is sucked out through the holes on the suction cup, so that a pressure difference is generated inside and outside, and the sample and the vacuum chuck for dicing machine are firmly squeezed together, so that the thin sheet sample is adsorbed and fixed. The vacuum suction cup is mainly suitable for samples that are not suitable for fixing by bonding methods and can withstand a certain suction force. Round vacuum chuck for spin coater can be used in conjunction with the syj-400 dicing and cutting machine manufactured by our company to adsorb and fix samples when cutting or grooving thin sheet samples; it can be used in conjunction with a vacuum spin coating machine to adsorb and fix thin sheet samples to be coated.

Advantages of round vacuum chuck for spin coater:

1.Round vacuum chuck for spin coater is made of durable material and can be used for a long time, reducing the frequency of replacement and increasing cost-effectiveness.

2.Round vacuum chuck for spin coater can be used with a variety of our equipment and has high flexibility.

3.Vacuum chuck for dicing machine does not require bonding materials and uses the vacuum principle to fix the sample, which is suitable for samples that are not suitable for bonding.

About us:

Our laboratory has successfully prepared thousands of samples, covering a variety of materials and application areas. At the same time, we have also welcomed customers from all over the world, and many international friends have visited us. They have deeply experienced our product quality and technological advantages by personally participating in the operation and testing of the laboratory. Every customer visit is a valuable opportunity for technical exchange and learning. Through interaction with customers, we continue to optimize our products and services to better meet market changes and needs.