Precision Cutting Machine

1. The automatic high-speed precision cutting machine has a wide range of applications.

2. The automatic high-speed precision cutting machine is easy to operate.

3. The automatic high-speed precision cutting machine offers high cutting precision.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction:

The automatic high-speed precision cutting machine is a versatile cutting device designed specifically for materials researchers. It is the ideal sample preparation equipment for research institutes, colleges and universities, as well as laboratory facilities in industrial and mining enterprises, with products sold worldwide. It is suitable for precision cutting of materials analysis samples, such as various crystals (sapphire, garnet, etc.), ceramics, cement, glass, rock samples, ore samples, metals, plastics, PCB boards, medical materials, dental materials, refractory materials, building materials, composite materials, and organic polymer materials. The automatic high-speed precision cutting machine is particularly suitable for cutting or slicing materials, and can also cut samples at certain angles. The spindle speed is infinitely adjustable, and the size of the sample being cut is adjusted by a digital caliper during the cutting process, ensuring precise size control. The automatic high-speed precision cutting machine is equipped with a cutting limit protection to prevent the clamp from being damaged by the saw blade. Depending on the type of material being cut, the SYJ-1000 precision cutting machine can use different cutting saw blades (such as sintered diamond blades, electroplated diamond blades, corundum blades, silicon carbide blades, cubic boron nitride blades). A cooling water box is located below the saw blade, which uses the rotation of the saw blade to bring the cooling liquid in the box to the sample, promptly removing the heat generated during the cutting process and thereby preventing the sample from overheating and altering its structure. The automatic high-speed precision cutting machine is compact, easy to operate, and highly adaptable, making it an indispensable cutting device for materials researchers.

Features:

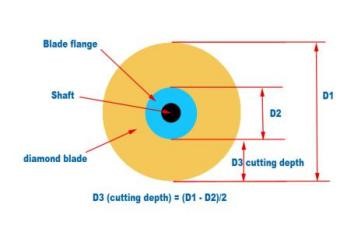

1. The precision cutting comes standard with a φ150 saw blade, but can use φ200 and φ100 saw blades as well.

2. It is equipped with a variety of fixtures to adapt to a variety of cutting (hand push saw workbench, hand push saw angle positioning ruler, gravity cutting two-dimensional cutting fixture, power cutting rotary cutting fixture, special-shaped sample fixture, small bench vise)

3. In terms of compatibility, the precision cutting is fitted with saw blades made of various materials (such as sintered diamond blades, electroplated diamond blades, corundum blades, silicon carbide blades, cubic boron nitride blades) to meet the cutting needs of different materials.

4. For product safety, the precision cutting is equipped with a limit device that allows for unattended cutting.

Technical Parameters:

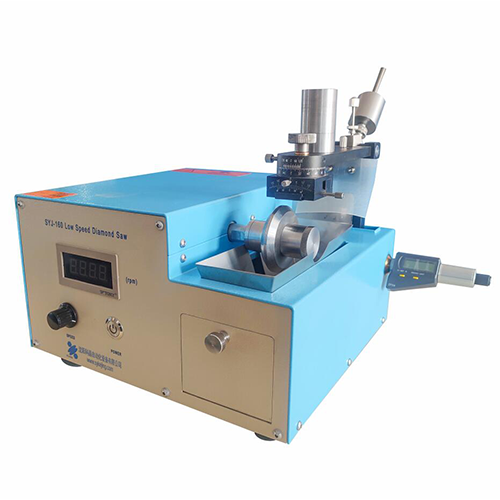

Product Name: | SYJ-1000 Precision Cutting Machine | |

Model: | SYJ-1000 | |

Installation Conditions: | This equipment requires operation under conditions of 25°C±15°C temperature and 55%Rh±10%Rh humidity. ·Water: The device is equipped with a self-circulating water tank. ·Electricity: AC220V 50Hz, with a requirement for good grounding. ·Gas: Not required. ·Workbench: Dimensions of 600mm×600mm×700mm, with a load capacity of over 50kg. ·Ventilation Device: Required. | |

| Main Parameters | ||

1. Power Supply Voltage | DC 220V | |

| 2. Spindle Speed | Minimum start speed to Maximum speed: 50~1500rpm | |

| 3. Cutting Stroke | ·Maximum stroke (cutting depth): ≈50mm |  |

| 4. Accuracy | Feed positioning accuracy: 0.01mm |  |

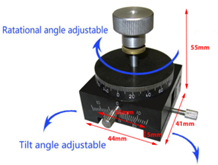

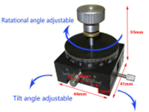

5. Gravity Cutting Fixture | ·Adjustable two-position fixture: Rotation of 360° in the horizontal direction and ±15° in the vertical direction. ·Equipped with a mini vice that can be installed on the two-dimensional fixture. ·Power cutting fixture allows automatic rotation of the sample during cutting. ·Special-shape fixture, cylindrical fixture, bench vise. |   |

6. Hand Saws Workbench | ·Hand saw cutting function equipped with an angle cutting gauge |  |

7. Circular Saw Blade Sizes | ·Ø150mm (includes three types of blades for cutting various materials) ·Silicon carbide blade: ·Corundum blade: ·Edge sintered diamond blade: |   |

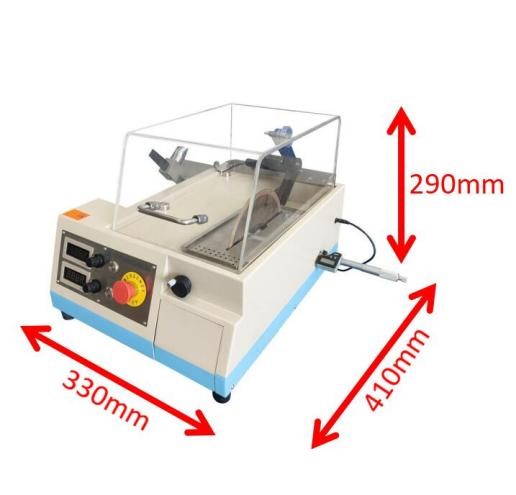

8. Product Specifications | ·Dimensions: 410mm×330mm×290mm ·Weight: 39kg |  |

Standard Accessories:

| Serial Number | Name | Quantity | Image Link |

| 1 | Adjustable Two-Dimensional Fixture | 1 Set |  |

| 2 | Vice | 1 Set |  |

| 3 | Hand Saws Workbench (including angle cutting gauge) | 1 Set |  |

| 4 | Gravity Cutting Fixture (power arm component, special-shape fixture, φ30 cylindrical fixture, small bench vise) | 1 Set |  |

| 5 | Power Cutting Head Fixture Saw Blade Shield | 1 Set |  |

| 6 | Aluminum Carrying Block (25mm×50mm×6mm) | 2 Set |  |

| 7 | Resin Ceramic Block (50mm×50mm×10mm) | 2 Set |  |

| 8 | Edge Sintered Diamond Saw Blade (Ø150mm×Ø12.7mm×0.6mm) | 1 Set |  |

| 9 | Silicon Carbide Saw Blade (Ø150mm×Ø12.7mm×0.6mm) | 5 Set |  |

| 10 | Corundum Saw Blade (Ø150mm×Ø12.7mm×0.6mm) | 5 Set |  |

| 11 | Saw Blade Shield (Ø62mm, Ø48mm, Ø35mm) | 3 Set |  |

| 12 | Paraffin Rods | 4 Set |  |

| 13 | Safety Goggles | 1 Set |  |

Optional Accessories:

| Serial Number | Name | Function Category | Image Link |

| 1 | Full Sintered Diamond Saw Blade (Ø150mm×Ø12.7mm×0.6mm) | (Optional) |  |

| 2 | Silicon Carbide Saw Blade (Ø150mm×Ø12.7mm×0.6mm) | (Optional) |  |

| 3 | Corundum Saw Blade (Ø150mm×Ø12.7mm×0.6mm) | (Optional) |  |

| 4 | Edge Sintered Diamond Saw Blade (Ø150mm×Ø12.7mm×0.6mm) | (Optional) |  |

Precautions:

1. During the cutting process, use cutting fluid with cooling powder, or liquids with anti-corrosion properties such as rust preventatives or emulsions, to avoid using water for cooling directly on the Gravity-fed Precision Sectioning Machine to prevent rusting of the equipment.

2. When stopping the machine, first reduce the RPM of the Gravity-fed Precision Sectioning Machine to zero before turning off the power switch, then remove the sample.

3. Before starting the Gravity-fed Precision Sectioning Machine, ensure that the sample is securely fixed and clamped, and turn the speed control knob counterclockwise to zero, then turn on the switch and increase the speed.

4. After each use, clean and protect the fixtures and saw blades of the Gravity-fed Precision Sectioning Machine, dry them, apply oil to prevent rust, and store them properly.

5. To prevent oxidation or contamination of the sample cutting surface, operate the Gravity-fed Precision Sectioning Machine inside a nitrogen-filled glove box (argon gas filling is excluded).

Warranty Period:

One-year warranty, lifetime technical support.

About Us:

Shenyang Kejing Auto-instrument Co., Ltd., established in May 2000 and committed to serving the scientific research community, offers a wide range of products for material analysis. The Metkon Automatic High-Speed Precision Cutting Machineinclude cutting, grinding, polishing, film coating, mixing, rolling & pressing, sintering, and analyzing equipment along with related consumables. The company aims to cater to the complete sets of sample preparation and analysis needs for various materials such as crystals, ceramics, metals, and more. With a focus on small-scale production for universities, research institutions, and factories, Shenyang Kejing strives to become a dynamic, trustworthy, and respected enterprise in the scientific instrumentation sector. The company is dedicated to using innovative technology to serve society and maintains a customer-centric approach as its fundamental mission.