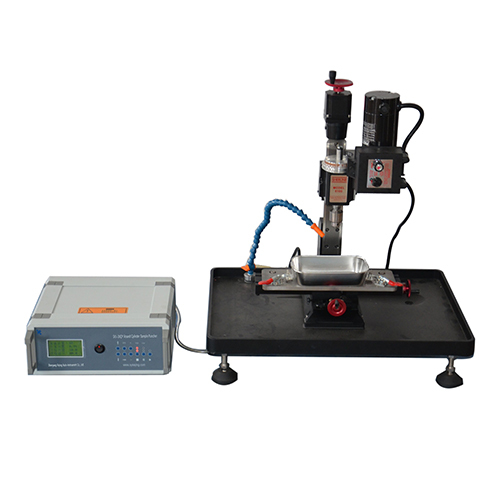

Precision CNC Round Cylinder Sample Puncher

1. Using Precision CNC cylindrical samplers of different specifications, cylindrical and annular samples can be obtained, and holes can also be drilled on the material.

2. The samples obtained using Precision CNC cylindrical sampler are neat and high in precision.

3. The Z axis is driven by a stepper motor, and the X and Y axes are manually adjusted.

4. The electric punching machine is equipped with a fast caliper and a cooling water tray.

5. The Cylindrical specimen punching machine is easy to use, simple to operate, and beautiful in appearance.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of CNC cylindrical sample punching machine:

SYJ-30QY CNC cylindrical sample punching machine is specially used for drilling cylindrical or annular samples from solid materials. It can be sampled manually or by using a controller to automatically control the feeding and withdrawal. The sampling accuracy can be controlled within a certain range. SYJ-30QY CNC cylindrical sample punching machine can take a wide range of samples, such as crystals, ceramics, metals, glass, rocks, cores, plastics, PCB boards, refractory materials, composite materials, etc. The sample sizes of the electric punching machine are more Ø3mm-Ø30mm, and there are no requirements for the shape and surface state of the sample. The minimum sampling size of the machine for brittle materials is Ø3mm, which is suitable for the sampling and preparation of electron microscope samples.

Technical parameters of Manual cylindrical punching machine:

Product Name | SYJ-30QY Round Cylinder Sample Puncher |

| Product Model | SYJ-30QY |

| Installation conditions of Manual cylindrical punching machine | 1. Cylindrical specimen punching machine is required to be used at a temperature of 25℃±15℃ and a humidity of 55%Rh±10%Rh. 2. Water: The Precision CNC cylindrical sampler is equipped with a water inlet and a drain port, which need to be connected to tap water and drainage by yourself. 3. Electricity: AC220V 50HZ. 4. Gas: None. 5. Workbench size: 700mm*600mm*700mm. 6. Ventilation device: required. |

Main parameters of Precision CNC cylindrical sampler | 1. input voltage: 220V 2. Driving motor power: 120w 3. Spindle speed: 70~2750rpm 4. travel distance: X-axis 200mm, Y-axis 80mm, Z-axis 100mm 5. Fast caliper force: 27kg 6. sample plate: 300mm×100mm×10mm 7. Sample plate washer: 180mm×75mm×5mm 8. Sampler: inner hole Ø30 |

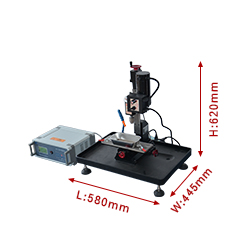

Product Dimension | Dimensions of Cylindrical specimen punching machine:: 580mm×445mm×620mm

|

Standard accessories of Manual cylindrical punching machine:

No. | Name | Qty | Picture |

1 | Sampler | 2 pcs | - |

2 | Sample Holding Plate | 1 pcs | - |

3 | Quick Caliper | 2 pairs | - |

4 | Water Tank | 1 pcs | - |

5 | Resin Bonded Ceramic | 2 pcs |  |

6 | Wax Bar | 4 pcs |

|

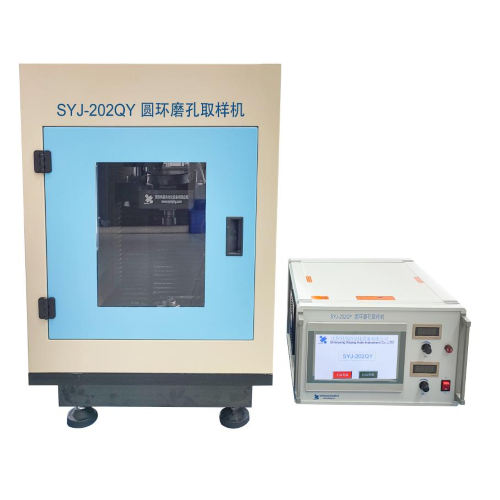

Optional accessories for Manual cylindrical punching machine:

Our services:

Our company provides Electric punching machines to meet the diverse needs of customers in the field of precision manufacturing. Our Electric punching machines have been recognized by many customers for their performance, stable quality and long-term durability. We not only provide a one-year limited warranty, but also lifetime support (excluding rusted parts of Electric punching machine products caused by improper storage conditions). We have a professional technical team that can provide customers with comprehensive service support in the selection, installation and commissioning, and operation training of Electric punching machines. No matter what problems you encounter during use, we will do our best to provide you with timely and effective solutions to make your production line run efficiently and stably. Choosing us means choosing the dual guarantee of quality and service.