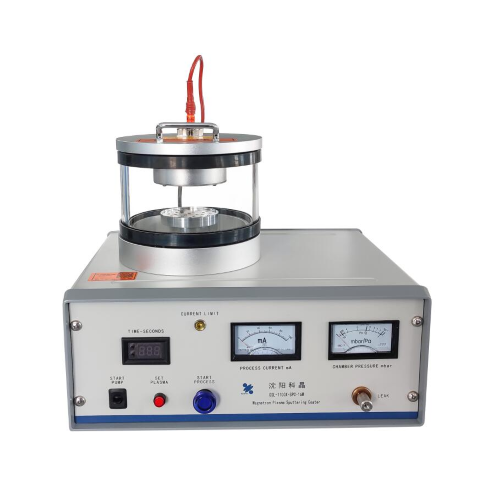

Magnetron Sputtering Coater

1. Vacuum magnetron sputtering coating machine can use a large-capacity sputtering vacuum chamber and a corresponding area sputtering target according to the gas ionization characteristics in the electric field to make the sputtering coating more uniform and pure.

2. The sputtering head of the vacuum magnetron sputtering coating machine adopts peltier cooling technology to obtain high-performance, fine-particle coatings.

3. The vacuum magnetron sputtering coating machine can use a water-cooled sputtering head and a water-cooled stage.

- Shenyang Kejing

- Shenyang, Liaoning

- 10 working days

- 50 sets

- Information

Introduction of magnetron sputter coating machines with water chiller:

GSL-1100X-SPC-16M magnetron sputter coating machines with water chiller uses the sputtering effect produced by particle bombardment of the target in a vacuum environment to eject target atoms or molecules from the solid surface and deposit on the substrate to form a thin film. It is a type of physical vapor deposition (PVD) thin film preparation technology. The simple, reliable and economical coating equipment designed is suitable for the preparation of various composite film samples in the laboratory and the production of experimental electrodes of non-conductive materials. Magnetron sputter coating machines with water chiller can be used in the laboratory to prepare scanning electron microscope samples, and magnetron sputter coating machines with water chiller are small in size, saving laboratory space; simple to operate, suitable for beginners.

Advantages of pvd sputter coater:

1. Pvd sputter coater is equipped with vacuum meter and sputtering current meter to monitor the working status in real time.

2. Pvd sputter coater can control the vacuum chamber pressure, ionization current and select the required ionization gas by adjusting the sputtering current controller and micro vacuum air valve to obtain the best coating effect.

3. The rubber seal ring on the edge of the bell jar of pvd sputter coater adopts a special design to ensure that the glass bell jar will not collapse during long-term use.

4. The ceramic sealed high-voltage electrode connector used by pvd sputter coater is more durable than the ordinary rubber seal.

Technical parameters of pvd sputter coater:

| Product name | GSL-1100X-SPC-16M Pvd Sputter Coater |

| Product model | GSL-1100X-SPC-16M |

| Installation conditions | This equipment is required to be used at an altitude of less than 1000m, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: The equipment needs to be equipped with a self-circulating cooling water machine (filled with pure water or deionized water). 2. Electricity: AC220V 50Hz, must be well grounded. 3. Gas: The equipment chamber needs to be filled with argon (purity above 99.99%), and an argon gas cylinder (with a pressure reducing valve) must be prepared. 4. Workbench: size 600mm×600mm×700mm, load-bearing capacity above 50kg. 5. Ventilation device: not required. |

| Main parameters | 1. Target: Ø50mm. 2. Vacuum chamber: Ø160mm×120mm. 3. Vacuum degree: ≤4×10-2mbar. 4. Max current: 50mA (optional 100mA). 5. Settable limit time: 9999s. 6. Micro vacuum air valve: connected to Ø3mm hose. 7. Limit voltage: 1600V DC. 8. Mechanical pump: 2L/s. 9. Target material: Size requirement: φ50mm×(0.1-0.5)mm (thickness). Suitable for sputtering Au, Ag, Cu and other metals (available in our company). 10. Product specifications: Size: 360mm×300mm×380mm. Weight: Overall weight: 50Kg. Net weight of main machine: 15Kg. |

Standard accessories of pvd sputter coater:

| NO. | Name | Qty | Picture |

| 1 | Gold Sputtering Target | 1 piece | -- |

| 2 | Inlet needle valve | 1 piece | -- |

| 3 | Fuse | 2 piece | -- |

Optional accessories of pvd sputter coater:

| NO. | Name | Function | Picture |

| 1 | Various sputtering targets such as gold, indium, silver, platinum, etc. | (Optional) | -- |

About us:

We not only have high standards in product quality, but also pay attention to details in logistics and packaging. The transportation process of precision instruments is extremely important. Once damaged, it will affect the normal production of customers. Our packaging team has undergone rigorous training and mastered the packaging skills of precision instruments. To this end, we have established a complete logistics system and cooperated with world-renowned logistics companies to allow you to receive products in a short time.