High Vacuum Magnetron Sputtering Instrument

1. This high vacuum magnetron sputtering coater is independently developed by us, and the preparation effect is intuitive and controllable.

2. High vacuum magnetron sputtering coater can be equipped with multiple target guns and replaced as needed.

3. High vacuum magnetron sputtering coater has high adaptability and good effect, far exceeding the same type of products in the same industry.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Introduction of magnetron sputtering equipment:

VTC-600G high vacuum magnetron sputtering coater is a newly independently developed coating equipment, which can be used to prepare single-layer or multi-layer ferroelectric films, conductive films, alloy films, semiconductor films, ceramic films, dielectric films, optical films, oxide films, hard films, polytetrafluoroethylene films, etc. VTC-600G Magnetron sputtering equipment can be equipped with multiple target guns, and the matching RF power supply is used for sputtering coating of non-conductive target materials, and the matching DC power supply is used for sputtering coating of conductive materials. Compared with similar equipment, Magnetron sputtering equipment is not only widely used, but also has the advantages of small size and easy operation. It is an ideal equipment for laboratory preparation of material films, especially suitable for laboratory research on solid electrolytes and OLEDs.

Main features of magnetron sputtering equipment:

·Vacuum magnetron sputtering instrument can be equipped with multiple target guns, and the matching RF power supply is used for sputtering coating of non-conductive target materials, and the matching DC power supply is used for sputtering coating of conductive materials (the target gun can be replaced at will according to customer needs).

·Vacuum magnetron sputtering instrument can prepare a variety of thin films and is widely used.

·Vacuum magnetron sputtering instrument is small in size and easy to operate.

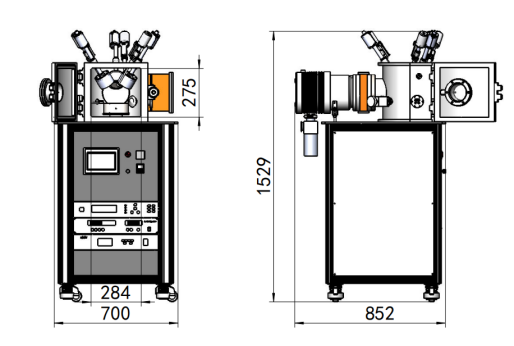

·The whole machine has a modular design, and the vacuum chamber, vacuum pump group, and control power supply are split designs, which can be adjusted according to the actual needs of users.

·The power supply can be selected according to the actual needs of the user. One power supply can control multiple target guns, or multiple power supplies can control a single target gun.

Technical Parameters of vacuum magnetron sputtering instrument:

Product name | VTC-600G High Vacuum Magnetron Sputtering Instrument | |

Product model | VTC-600G | |

Main parameters | 1. Structure: desktop front door structure, rear exhaust system. | |

2. Ultimate vacuum: 6.0X10-5Pa. | ||

3. Leakage rate: 1h≤0.5Pa. | ||

| 4. The exhaust time is about 20 minutes from atmosphere to 5.0X10-3. | ||

5. Vacuum pump group: mechanical pump + molecular pump. | ||

6. Sample stage: φ140, room temperature -500℃, accuracy ±1℃ (temperature can be increased according to actual needs) rotation adjustable within 5rpm-20rpm. The bias function can be added according to customer needs to achieve higher quality coating. | ||

7. Gas filling system: 2 mass flow meters (Argon/nitrogen each). | ||

8. The angle between the target head and the center axis of the sample stage is 34°. | ||

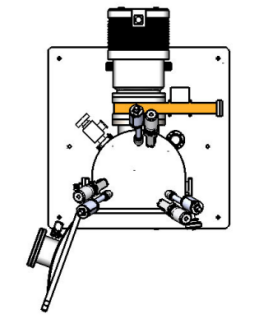

9. Number of target heads: 3 (120° to each other). | ||

10. Target gun cooling method: water cooling. | ||

11. Target material size: φ2″, thickness 0.1-5mm (thickness varies due to different target materials). | ||

12. Product specifications: · Dimensions: Complete machine size: 700mm×852mm×1529mm; |  | |

Optional accessories of magnetron sputtering equipment:

| NO. | Name | Function | Picture |

| 1 | Sample stage baffle | (optional) |

|

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics:

About us:

We are a high-tech company focusing on the research and development and production of coating machines, and we are also a leader in the industry. Each of our products has been carefully designed and strictly tested by designers, and has a high level in equipment performance and accuracy. We not only focus on the product itself, but also pay attention to technological innovation and customer relationships, and are committed to providing high-level experimental instruments to global customers.