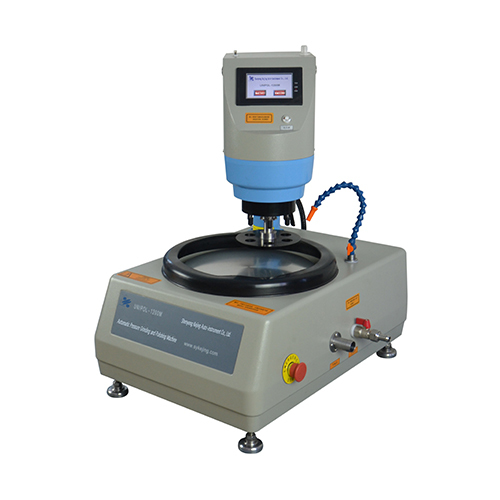

Automatic Pressure Lapping & Polishing Machine

1.Automatic pressure grinding and polishing machine provides an automated grinding and polishing process, reducing manual intervention and improving production efficiency.

2.Automatic pressure grinding and polishing machine uses a mechanical pressurization system to grind the sample under stable pressure.

3.Automatic pressure grinding and polishing machine can effectively reduce scratches on the grinding surface and improve the smoothness of the sample.

- Shenyang Kejing

- Shenyang, China

- 44 working days

- 50 sets

- Information

- Video

Introduction of automatic grinding and polishing machine:

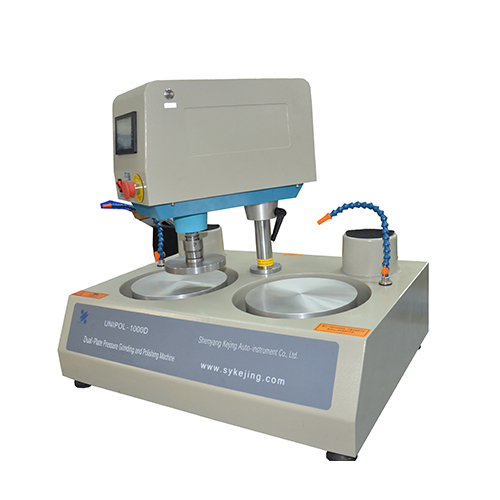

UNIPOL-800M multi-point mechanical pressure grinding and polishing machine adopts three-point mechanical spring pressure. Under the action of pressure spring, the top column presses the sample in the carrier plate onto the rotating grinding and polishing plate. The automatic grinding and polishing machine makes the sample grind and polish under a certain pressure as the plate moves, thus realizing the positioning and grinding and polishing of the sample. The automatic grinding and polishing machine also has a mechanical support arm grinding and polishing station, which can be used for grinding and polishing of easy-to-cleave and easy-to-break materials. During the grinding and polishing process, the gravity carrier plate with the sample fixed is ground and polished with the swing of the mechanical swing arm, and it also rotates at the same time. The scratches on the surface of the ground sample are uniform and easy to polish. The automatic grinding and polishing machine is mainly used in the field of material research. It is widely used in the automatic grinding and polishing of metal, ceramic, glass, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), rock samples, mineral samples, composite materials, polymer materials and other material samples in laboratories of colleges and universities, scientific research institutes, as well as small-scale production in factories. The automatic grinding and polishing machine is a dual-purpose pressure grinding and polishing machine that meets the grinding conditions of most materials.

Main features of automatic pressure grinding and polishing machine:

1. Scientific research pressure polishing machine is equipped with multi-point loading pressure, and the spring pressure is adjusted by manually adjusting the nut.

2. Scientific research pressure polishing machine is equipped with a mechanical support arm grinding and polishing station.

3. Scientific research pressure polishing machine has the characteristics of excellent performance, simple operation and wide application range.

Technical parameters of scientific research pressure polishing machine:

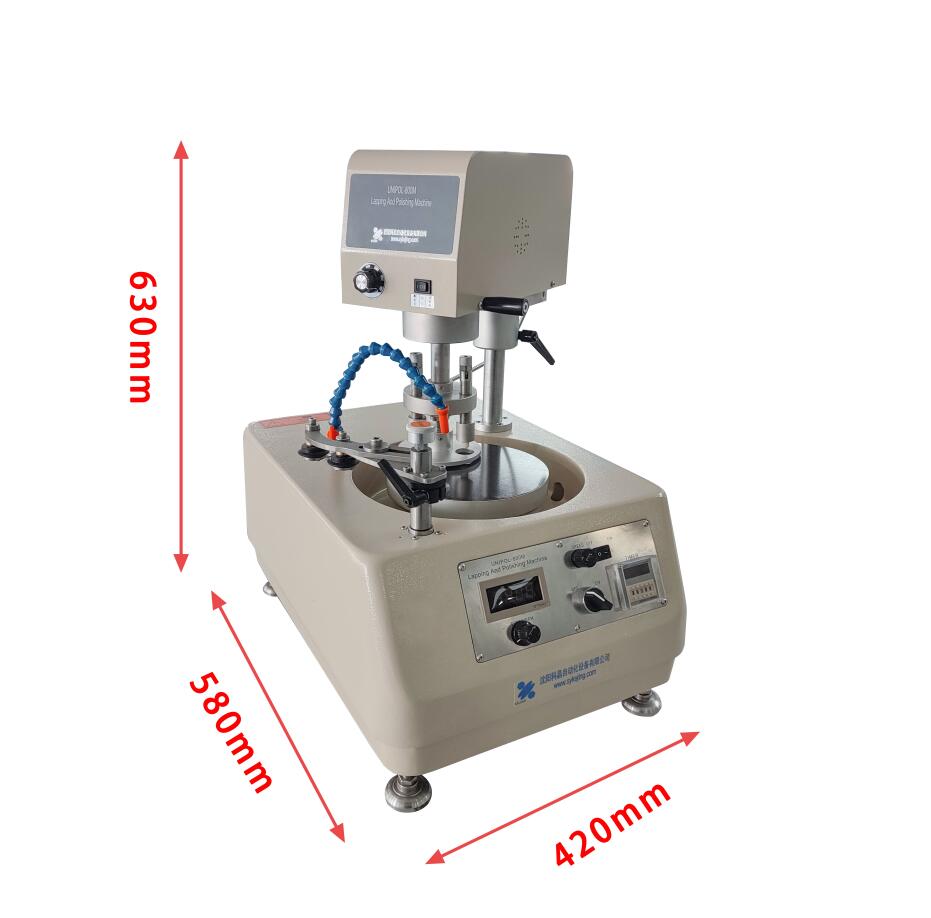

Product Name | UNIPOL-800M Multi-Point Mechanical Pressure Grinding and Polishing Machine |

Product Model | UNIPOL-800M |

Main Parameters (Specification) | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Power supply: Single phase: AC220V 50Hz national standard three-pole socket 10A (the socket must have a good safety protection grounding wire). 4. Cooling water: The equipment is equipped with an inlet and a drain, and you need to connect the tap water and drainage pipeline by yourself. 5. Air source: No requirement for standard equipment. 6. Workbench: It is recommended to use it on an operating table or desktop with a load of more than 150kg. 7. Ventilation device: Good ventilation environment, no special ventilation device requirements are required. 8. Auxiliary equipment (purchased separately): Recommended: 1. HEATER-3040 or 250 heating platform. 2. SKCH-1 precision thickness gauge. 3. SZKD-series dripper. 4. SKCS-1 blow dryer. |

| The main parameters | 1. Equipment power supply port: AC220V 50Hz. 2. Total power: 300W. 3. Grinding and polishing disc diameter: Φ203 mm. 4. Upper sample chuck diameter: Ø110mm, sample load φ25mmX3 (other sizes can be customized). 5. Gravity sample loading disc diameter: Φ80 mm (flat plate) with repair ring. 6. Number of lower swing stations (swinging mechanical arm): 1 station. 7. Upper disc main drive motor: AC220V 25W (reduction motor). 8. Lower disc main drive motor: DC110V 245W. 9. Upper sample loading disc speed: 0-60rpm (speed adjustable). 10. Lower grinding and polishing disc speed: 0-400rpm (speed adjustment). 11. Timing function: Can be set: hours, minutes, seconds; setting range: between 0-99h. |

Product Specifications | 12. Product specifications: Dimensions: L420×W580×H630mm. Net weight: ≈75Kg.

|

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

Since the establishment of the company, we have always focused on the research and development and manufacturing of equipment, and are committed to providing comprehensive services to colleges and universities, scientific research institutions and manufacturing companies. Our products cover multiple fields, and while meeting the preparation and analysis needs of various materials, they also help laboratory research and small-scale production. With high-quality products and excellent services, we have won the trust of a wide range of customers. Today, our products have been exported to the United States, Japan and other countries, and are well received by customers.