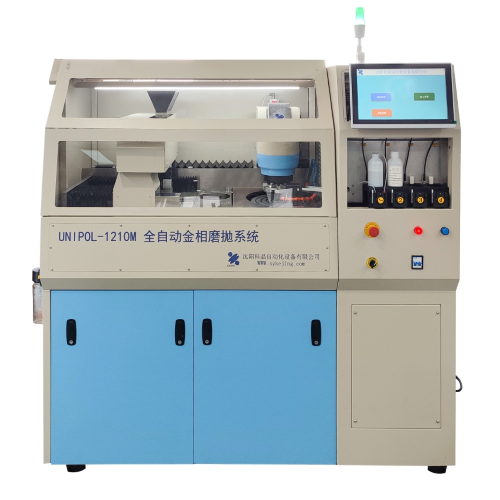

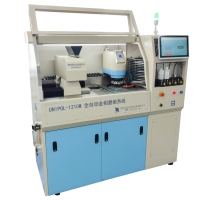

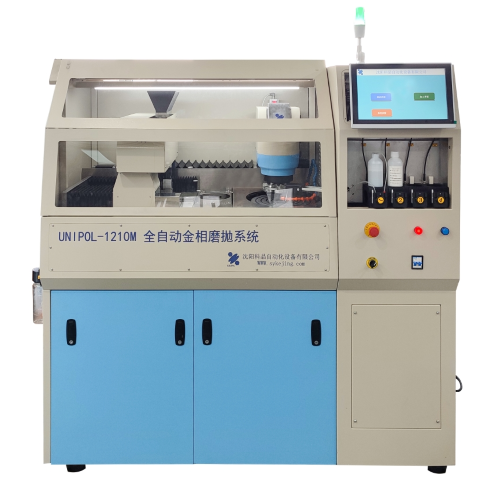

Automatic Metallographical Grinding And Polishing System

1. Automatic grinding and polishing machine can fully automatically inlay + grind and polish + clean at one time, saving manpower. It has 6 mounting stations and can complete up to 6 samples at the same time.

2. The automatic grinding and polishing machine can use the inlay or grinding and polishing unit alone, or the inlay/grinding and polishing unit can be used in combination for flexible matching.

3. The inlay pressure, temperature and time of the automatic grinding and polishing machine can be adjusted arbitrarily and change with the different materials.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of automatic metallographic grinding and polishing machine:

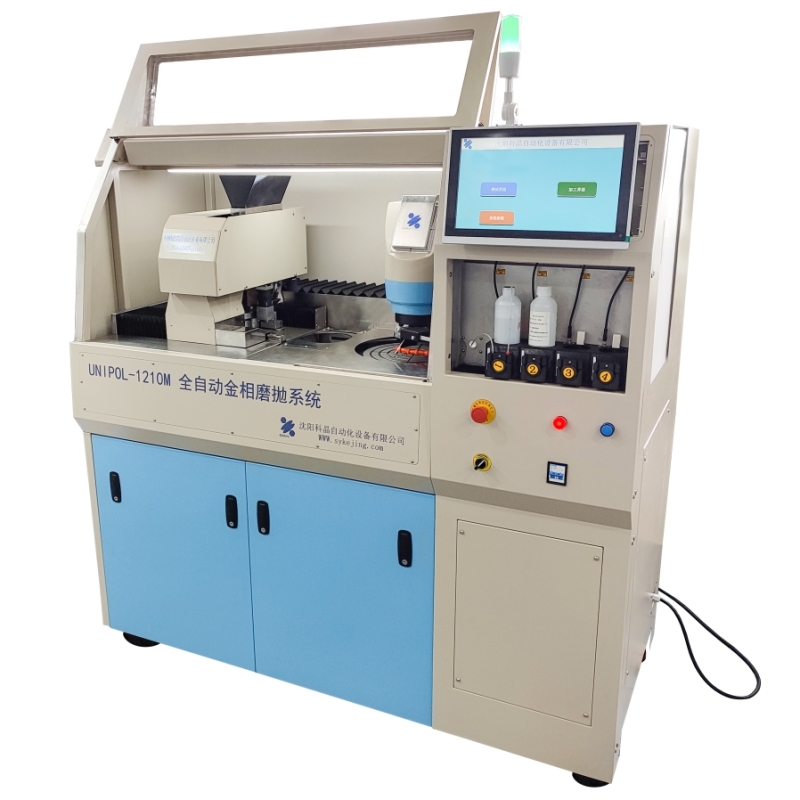

UNIPOL-1210M automatic metallographic grinding and polishing machine, including automatic inlay, grinding and polishing and cleaning units, can realize the fully programmed automatic process from inlay-sampling-grinding-cleaning-polishing-cleaning. Through the touch screen operation, all parameters from inlay to grinding, polishing and cleaning can be accurately controlled, and the parameter settings can be archived. The program of automatic metallographic grinding and polishing machine can be started with one button, so as to achieve the consistency of sample automatic operation. In addition, the inlay, grinding, polishing and cleaning units can be used flexibly alone or in combination, which is suitable for repeatability and consistency experiments of materials such as metals, ceramics, rock samples, electronic devices, and workers in the material research industry who need large-scale sample preparation.

Advantages of automatic metallographic grinding and polishing machine:

· All-in-One Automation: Integrates mounting, grinding, polishing, and cleaning in a single workflow, greatly reducing labor.

· High Throughput: Up to 6 mounting stations allow simultaneous processing of multiple samples.

· Flexible Operation: Mounting and grinding/polishing units can be used independently or combined as needed.

· Customizable Mounting: Adjustable pressure, temperature, and time to suit different materials.

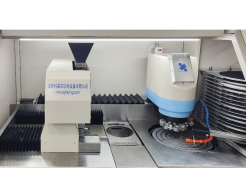

· Automatic Transfer: Mounted samples are automatically delivered to the grinding/polishing unit.

· Efficient Grinding & Polishing: Automatic change of abrasive papers and polishing pads; pneumatic single-point loading ensures even pressure.

· Powerful Performance: Dual-plate speed control with low-speed, high-torque design for reliable operation.

· Precise Pressure Control: Air pressure adjusted via throttle valve to match material properties.

· Versatile Slurry Supply: Multiple dispensing systems for flexible application.

· Durable & Safe: Steel housing with baked enamel finish and protective dust cover.

· Smart Control: Touchscreen interface with programmable software and memory for multiple process settings.

· Material Database: Built-in database supports consistent results for metals, ceramics, rocks, and electronic components.

· Clean Processing: Ultrasonic and high-pressure water cleaning ensures contamination-free samples for the next step.

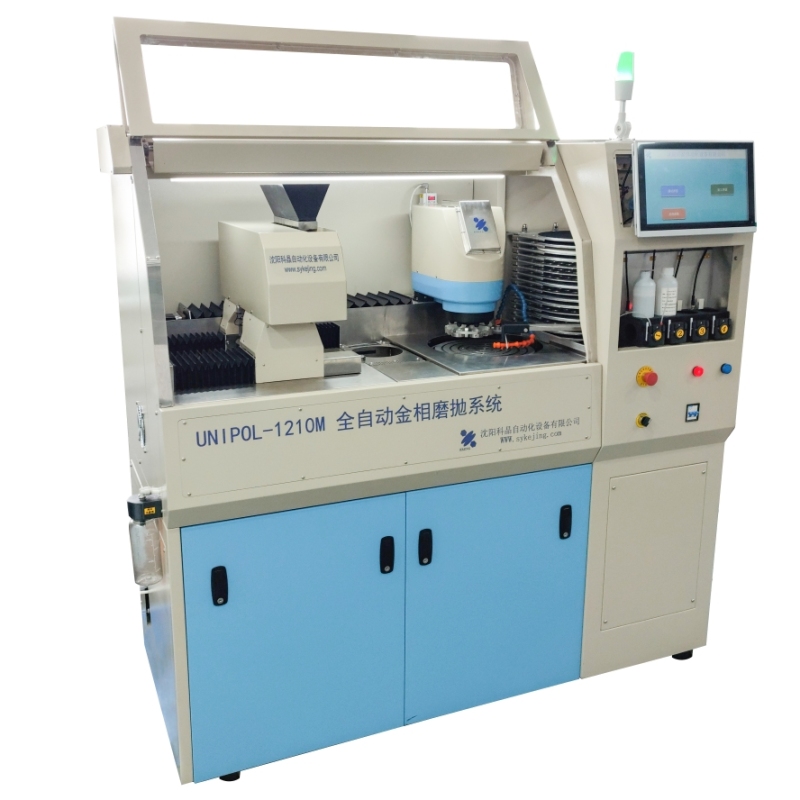

Technical parameters of automatic grinding and polishing machine:

| Product name | UNIPOL-1210M Fully Automatic Metallographic Grinding And Polishing System | |

| Product model | UNIPOL-1210M | |

| Main parameters | 1. Mosaic unit

| 1. Number of hot mountings per time: 6. 2. Hot mounting diameter: 30mm (height not more than 35mm). 3. Driving mode: fully automatic electric hydraulic. 4. Heating temperature: 180℃. 5. Heating time: 1-30min. 6. Cooling time: 1-30min. 7. Heating power: 1200W. 8. Single-station clamping force: 220kg. |

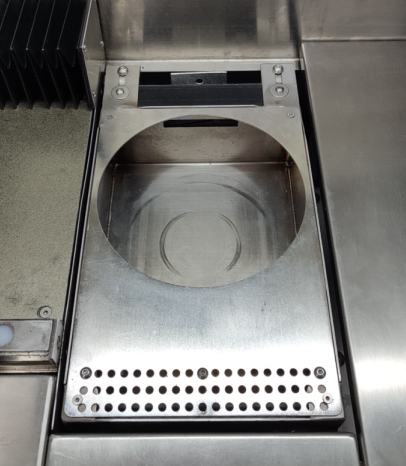

2. Grinding and polishing unit

| 1. The grinding and polishing disc adopts vacuum adsorption. 2. Number of grinding and polishing discs: 1. 3. Grinding and polishing disc size: φ300mm. 4. Grinding and polishing disc speed: 50-500rpm. 5. Sample loading disc aperture: φ30mm. 6. Sample loading disc speed: 10-60rpm. 7. Multi-point center loading pressure, pressure is controlled and adjusted by throttle valve. 8. Single sample Max loading force: 1-5kg | |

3. Storage unit

| 1. Automatically change the grinding sandpaper and polishing pad through program settings. 2. Max can store 16 sets of grinding and polishing pads, and the replacement order can be set. 3. Fixed on the grinding and polishing disc through vacuum adsorption. 4. The grinding/polishing time and number of times can be set through the program. | |

4. Cleaning unit

| 1. Equipped with water inlet and outlet. 2. Equipped with ultrasonic cleaning. 3. Equipped with high-pressure water flow cleaning. 4. Equipped with waste recovery device. | |

5. Grinding and polishing fluid equipment

| 1. Water, grinding paste × 1。 2. Suspension × 2. 3. Reserve 1 channel. | |

6. Others

| 1. After the inlay is completed, the grinding head automatically grabs the sample to the grinding and polishing disc. 2. Automatically replace sandpaper of different grits (coarse grinding, fine grinding) during the grinding process. 3. Automatically replace the polishing pad of the corresponding material during the polishing process. 4. Automatically drip the required water or grinding and polishing liquid. 5. Automatically grab the sample to the cleaning unit for cleaning. 6. The touch operation screen displays the status of each process in real time. 7. All the above can be completed and stored by setting parameters, and started with one button. | |

| 7. Product Specifications | · Dimensions:L1760mm×W790mm×H1750mm · Weight:about 950kg | |

About us:

We have advanced production equipment and strict quality management system, so that every product meets international standards. Our R & D team continues to innovate and is committed to improving product design based on market demand and customer feedback to provide more accurate and efficient solutions. With years of industry experience and technical accumulation, we have established a good reputation in the industry and won favorable comments from many customers.