Automatic Grinding and Polishing System

1.Metal polishing and grinding workstation fully automatic grinding and polishing + cleaning can be completed in one go, saving manpower.

2.The grinding disc of the metal polishing and grinding workstation is vacuum-adsorbed on the lower disc. During grinding, the rotation speed of the lower disc of the grinding disc can be adjusted arbitrarily.

3.The metal polishing and grinding workstation can automatically replace abrasive sandpaper and polishing pads of different grits during work, and can store 16 sets.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of grinding and polishing machine:

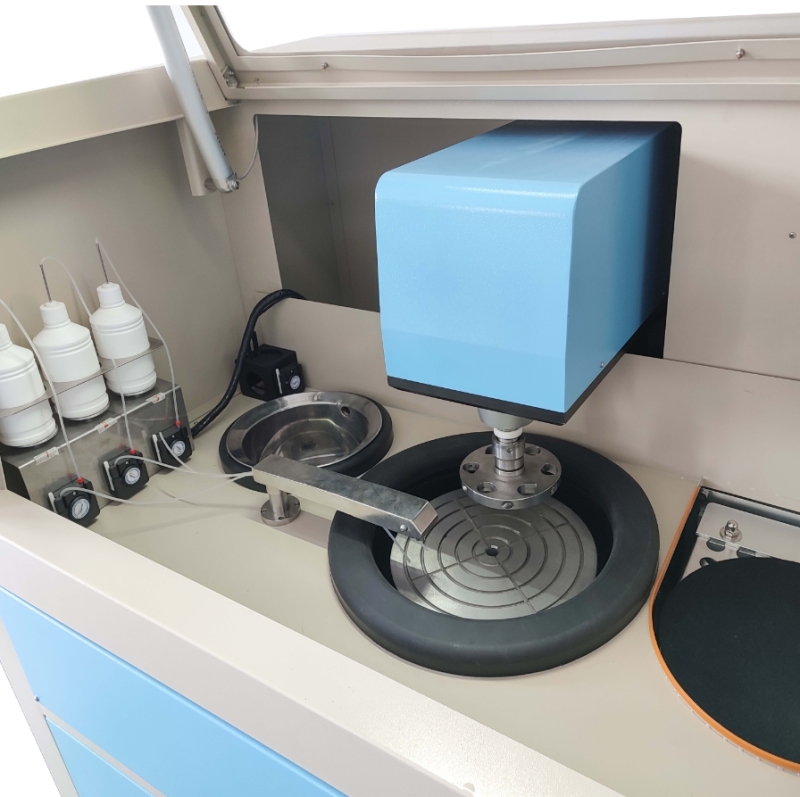

UNIPOL-1220S automatic grinding workstation includes automatic grinding, polishing and cleaning units, which can realize the fully programmed automatic process from grinding-cleaning-polishing-cleaning. All parameters of grinding, polishing and cleaning can be accurately controlled and set through touch screen operation. The parameters can be archived. The grinding and polishing machine can automatically replace the grinding sandpaper or polishing pad during operation, and start the program with one button, so as to achieve the consistency of sample automatic operation. The grinding and polishing machine is suitable for repeatability and consistency experiments of materials such as metals, ceramics, rock samples, and electronic devices.

Advantages of grinding and polishing machine:

1. Fully automatic grinding, polishing, and cleaning completed in one operation, saving labor.

2. The grinding plate is vacuum-adsorbed onto the lower plate, and its rotation speed can be freely adjusted during operation.

3. Different grit sizes of abrasive papers and polishing pads can be automatically replaced during the grinding and polishing process, with up to 16 sets stored.

4. Uses a mechanical loading method with adjustable pressure; the required pressure can be set according to different sample materials, up to a maximum of 30 kg.

5. Equipped with three peristaltic pumps for slurry delivery, offering high flexibility.

6. The machine housing is made of steel with a baked enamel finish, ensuring durability and safety, and includes a dust cover.

7. User-friendly touchscreen interface with a programmable software system.

8. Includes a multi-material database to ensure repeatability and consistency of experiments for metals, ceramics, rock samples, electronic devices, and more.

9. Ultrasonic cleaning of samples ensures that no residue from the previous process contaminates the next step.

Technical parameters of grinding and polishing machine:

| Product name | UNIPOL-1220S Metal Polishing and Grinding Workstation | |

| Product model | UNIPOL-1220S | |

| Main parameters | 1. Mosaic unit

| 1. Upper plate diameter: φ160mm. 2. Upper plate speed: 20-350rpm. 3. Max loading pressure: 30kg. 4. Lower grinding plate diameter: 300mm. 5. Lower grinding plate speed: 20-378rpm. 6. Lower grinding plate adopts vacuum adsorption method. 7. Waterproof ring can be raised and lowered. |

2. Grinding and polishing unit

| 1. Cleaning method: ultrasonic + clean water flushing. 2. Equipped with a water level detection switch. 3. Equipped with a solenoid valve to switch water inlet and water outlet. | |

3. Storage unit

| 1. Automatically replace grinding sandpaper and polishing pads through program settings. 2. Max. 16 sets of φ300mm grinding and polishing pads can be stored, and the replacement sequence can be set. 3. Fixed on the grinding and polishing disc through vacuum adsorption. 4. Grinding/polishing time and number can be set through program. 5. Electric lifting and feeding method is adopted. | |

4. Grinding and polishing fluid equipment

| 1. Use a peristaltic pump to drive the dripping system. 2. 3 sets of drippers are standard, and 6 sets of drippers are optional for Max. 3. Automatically detect whether the dripping bottle is lacking liquid. | |

| 5. Dimensions | Length × width × height: 1600 mm×1002mm×1688mm. | |

About us:

Our goal has always been to provide our customers with an excellent service experience, especially in logistics and packaging. In terms of packaging, we strictly select high-quality wooden boxes and follow strict standards to ensure that products are not damaged during transportation. The packaging team carefully inspects each product to ensure compliance with export requirements and reduce possible risks of damage during transportation.