Arc Melting System Accessories

Accessories for arc melting furnaces

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Technical Parameters

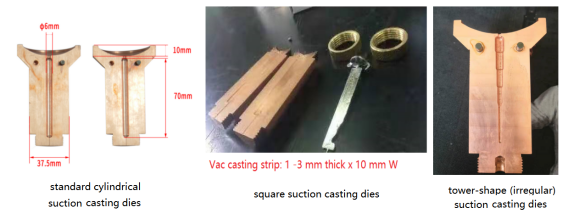

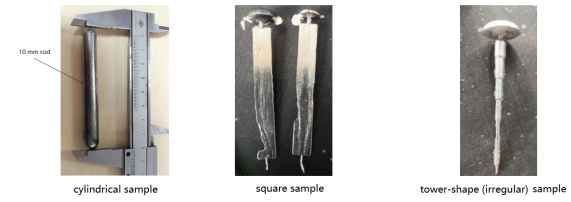

Product Name | Suction Casting Set for Metal Melting |

Major Parameters (Specification) | 1. The vacuum suction casting device can suction cast a standard round bar with a length of 70mm and a diameter of 6mm, and can also suction cast a cuboid with a width of 10mm and a thickness of 1-3mm, or special shapes. Please contact the sales staff for details. 2. By pumping the copper suction casting die, the molten metal can quickly enter the copper die to obtain metal blocks with smaller shrinkage. 3. The water-cooled copper crucible has 7 cavities, which can be changed appropriately according to customer requirements. 4. The size of the middle cavity is Φ30*10mm, and the bottom is equipped with suction casting device, electric valve, and foot switch control. 5. The size of the other 6 cavities is Φ25*8mm. |

| |

|

The metal melting and tube-sealing kit/suite is a special equipment for smelting various metal samples under vacuum conditions. It is mainly used for preparation of various metal samples as well as research on metal tube sealing and welding.

Technical Parameters

Product Name | metal smelting and tube-sealing kit/suite |

Major Parameters (Specification) | 1. Arc melting chamber: φ200mm×300mm. High-grade stainless steel plate with surface treated by electrochemical method is selected. 2. Smelting sample: weight ≤15g (calibrated by stainless steel) per smelting pool, total 4 smelting cavities. 3. Tube-sealing workstation: capable of welding tantalum tube with a diameter of φ5-φ30mm and the length of 50-100mm; automatically rotary workstation, and adjustable speed from 0 to 45rpms 4. Vacuum degree: standard mechanical pump: 6.0E-1Pa. If additional molecular pump is required, it should reach 5.0E-3Pa (standard configuration does not include the vacuum gauge). 5. Arcing method: high frequency arcing 6. Rated input power: 10.4 kVA 7. Cooling method: circulating water cooling |

Cautions | 1. Do not loosen the outer nut during any process, otherwise the electrode will leak water. 2. The whole machine should be placed in a dry and clean environment. 3. Regularly check whether the pipeline is unobstructed and remove the water scale in time. The movable joint ball in the middle of the electrode rod needs to be frequently applied/smeared/coated with some vacuum grease. This helps reduce wear of seals, improve rod flexibility, and increase the sealing effect of the melting chamber. 4. The melting chamber should be kept clean, especially the front and rear observation windows, copper crucibles and other important parts. The equipment needs to be evacuated to a vacuum state when not in use. |

Logistics