4 Heads Vacuum Arc Melting System

AM-400 Four-Arc Source Melting Furnace

- Shenyang Kejing

- Shenyang, China

- 44 working days

- 10 sets

- Information

Technical Parameters

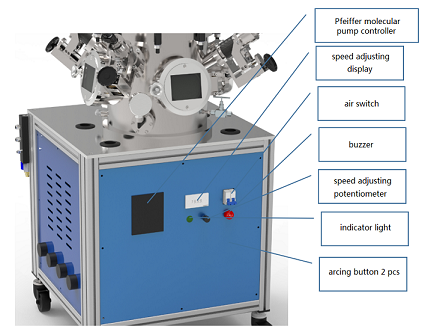

Product Name | AM-400 Four-Arc Source Melting Furnace |

Installation conditions | This equipment is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: The equipment is equipped with a self-circulating cooling water machine (filled with pure water or deionized water) 2. Electricity: AC380V 50Hz, must have good grounding 3. Gas: The equipment chamber needs to be filled with argon gas (purity 99.99% or more), and argon gas cylinders are required (with Ø6mm double ferrule joints) and pressure reducing valve 4. Workbench: floor type, area for installation: 2.5M×1M 5. Ventilation device: needed |

Major parameters | 1. Equipment ultimate vacuum: 8×10-4 Pa 2. Equipment power: <60kW 3. Equipment working pressure: -0.5MPa 4. System vacuum leak rate: 5.0×10-7 Pa.l/S 5. Pumping speed: pumping from the atmosphere to 7×10-3Pa≤30min. 6. Maintain the vacuum degree: the vacuum degree of the vacuum chamber shall not be lower than 10Pa after 12 hours of shutdown 7. Melting crucible: φ100×15mm, smelting 300g 8. Sample stage speed: 1 to 20 rpm, continuously adjustable In order to ensure the safe use of the equipment, system detection and protection functions are adopted, such as: water shortage and undervoltage detection and protection, strong power phase sequence detection and protection, temperature detection and protection, vacuum system detection and protection, etc. |

Product specification | 1. After the filling is completed, turn on the power switch of the equipment and adjust the crucible speed (1~20 rpm). 2. Operate the SPD/Pfeiffer HICube80 molecular pump unit to evacuate to 10-3Pa, close the manual flapper/buffer valve, and open the manual valve to charge the pressure to -0.03MPa. 3. Turn on the welding machine, adjust the current of the argon arc welding machine, and press the arcing buttons (2 pcs).

|

Standard Accessories

No. | name | specification (model) | qty |

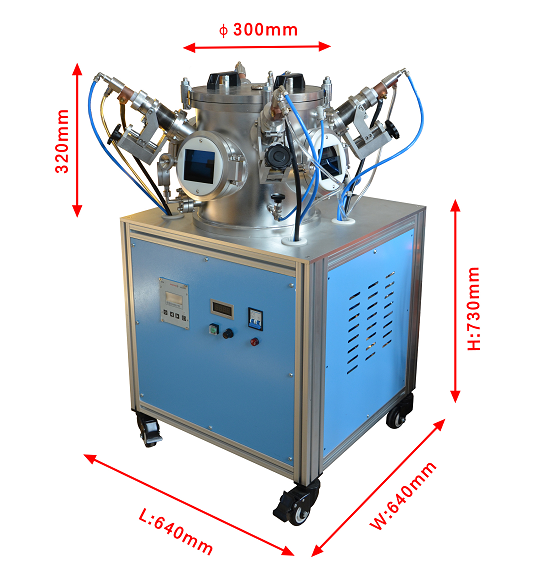

1 | Main Vacuum Chamber | Φ300×320 | 1 set |

2 | Bench Bracket | 640×640×730 | 1 set |

3 | Molecular Pump Set | HICube80 | 1 set |

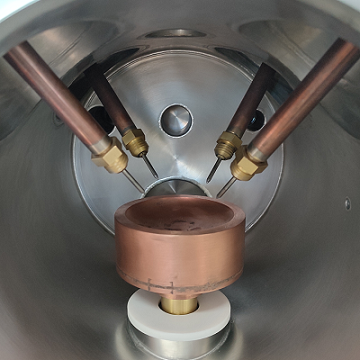

4 | Rotary Melting Crucible | One cavity of 100×15 | 1 set |

5 | Lifting Water-Cooling Electrode | 4mm W-needle | 4 sets |

6 | Sampling Door with Observation Window | 100 | 3 pcs |

7 | Manual 1/4 Ferrule Needle Valve | - | 2 pcs |

8 | Argon-Arc Welding Machine | WSM-6302 | 2 sets |

9 | High Vacuum Manual Flapper/Buffer Valve | GD-J63B(LF) | 1 set |

10 | Circulating Water Cooling Machine | KJ(CW)-6200 | 1 set |

11 | Pressure Gauge | -0.1~0.15Mpa | 1 set |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics