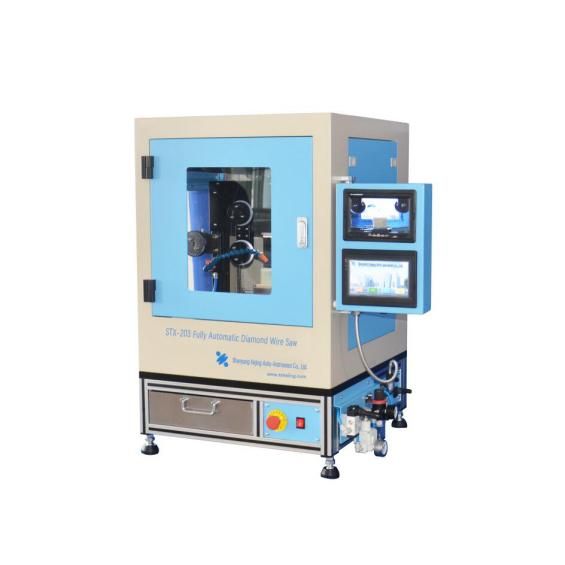

STX-203 Fully Automatic Diamond Wire saw meets precision cutting requirements

2024-07-22 13:43The fully automatic diamond wire cutting machine is a high-precision and high-efficiency cutting device that uses diamond wire as a cutting tool. It uses the high-speed reciprocating motion of the diamond wire and the relative grinding motion between the cut object to achieve precise cutting of various hard and brittle materials. It is widely used in ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials and biomedical materials.

The STX-203 Fully Automatic Diamond Wire produced by our company is designed for material researchers and is used for precision cutting of brittle material samples. It can slice and cut materials, and the rotating turntable can also cut samples at a certain angle. Materials that can be cut include ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials.

The STX-203 Fully Automatic Diamond Wire is a continuous cutting diamond wire cutting machine. After setting the cutting program, the sample is fed continuously without manual adjustment. The sample size after cutting is highly accurate. The cutting wire of The STX-203 Fully Automatic Diamond Wire adopts a single wire reciprocating motion mode. The length of the usable wire is long, the service life of the wire is long, and the cutting efficiency is improved. When it is used for ultra-thin precision cutting, the thickness of the slice can reach 0.08mm.

The installation conditions of The STX-203 Fully Automatic DiamondWire include some special requirements. First of all, for temperature and humidity, it is best to be 10-85%RH at 25℃ without condensation, and the temperature is within the range of 0-45℃; there is no strong vibration source and corrosive gas around the equipment; coolant is required, and cutting oil is recommended; the power supply is single-phase AC220V 50Hz national standard three-pole socket 10A must be well grounded; the workbench is recommended to be a solid cement table. Cleaning and maintenance of The STX-203 Fully Automatic DiamondWire requires regular cleaning of the cutting machine's cutting table, cutting liquid tank, cutting wire and other components. Regularly check the wear of the cutting wire and replace the damaged cutting wire in time to maintain a longer service life.

Shenyang Kejing has many years of experience in producing STX-203 Fully Automatic Diamond Wire. It has hundreds of products covering material cutting, grinding, polishing, coating, coating, mixing, rolling, sintering, analysis and other fields as well as related consumables. It is committed to becoming a well-known domestic brand of material analysis equipment and providing one-stop services for R&D, production, sales, logistics and after-sales installation.