Features And Applications Of The Two Major Categories Of Precision CNC Dicing Saw

2024-08-03 09:18Features and applications of the two major categories of Precision CNC Dicing Saw:

Grinding wheel Precision CNC Dicing Saw is a equipment that integrates water-gas electricity, air static pressure high-speed spindle, precision mechanical transmission, sensor and automatic control technologies. It is mainly used for dicing processing of materials such as silicon integrated circuits, light-emitting diodes, lithium niobate, piezoelectric ceramics, gallium arsenide, sapphire, aluminum oxide, iron oxide, quartz, glass, ceramics, solar cells, etc. Among them, the grinding wheel dicing machine is also called precision grinding wheel cutting machine in China.

The advantages of grinding wheel Precision CNC Dicing Saw include:

1. Wide processing range: The grinding wheel dicing machine can be applied to the dicing processing of a variety of materials, such as metals, non-metals, semiconductors, etc.

2. High processing accuracy: The grinding wheel dicing machine adopts precision mechanical transmission and sensor technology to ensure the accuracy and stability of dicing processing.

3. Efficient processing: The grinding wheel dicing machine can perform high-speed dicing processing to improve production efficiency.

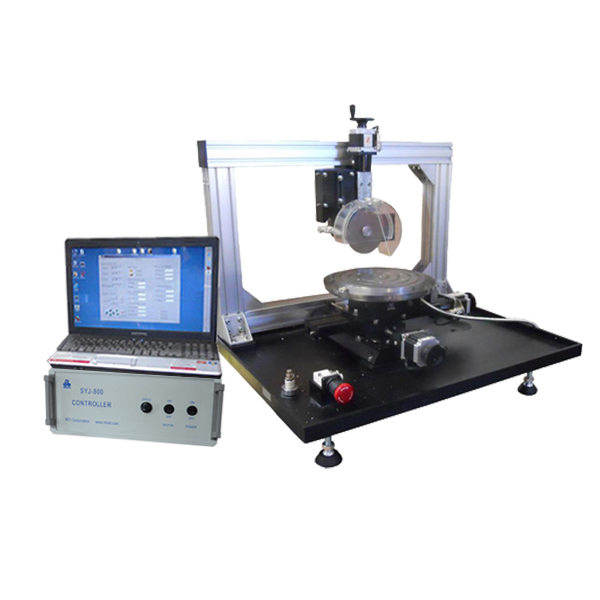

Our SYJ-800 CNC dicing and cutting machine is a continuous cutting machine that uses computer three-dimensional control. The sample cutting process is controlled by programming on the computer. It is mainly suitable for dicing and grooving crystals, ceramics, glass and various thin sheet materials. It can also be used for cutting various materials such as various crystals, ceramics, glass, minerals, metals and other materials. Different cutting saw blades can be selected according to the different materials of the cut samples. The sample cutting table is equipped with a waterproof cover to prevent splashing. It is an ideal precision cutting equipment for laboratories and production units to process large crystal wafers.