An Advanced Machine Designed For Precise Cutting Of Curved Shapes

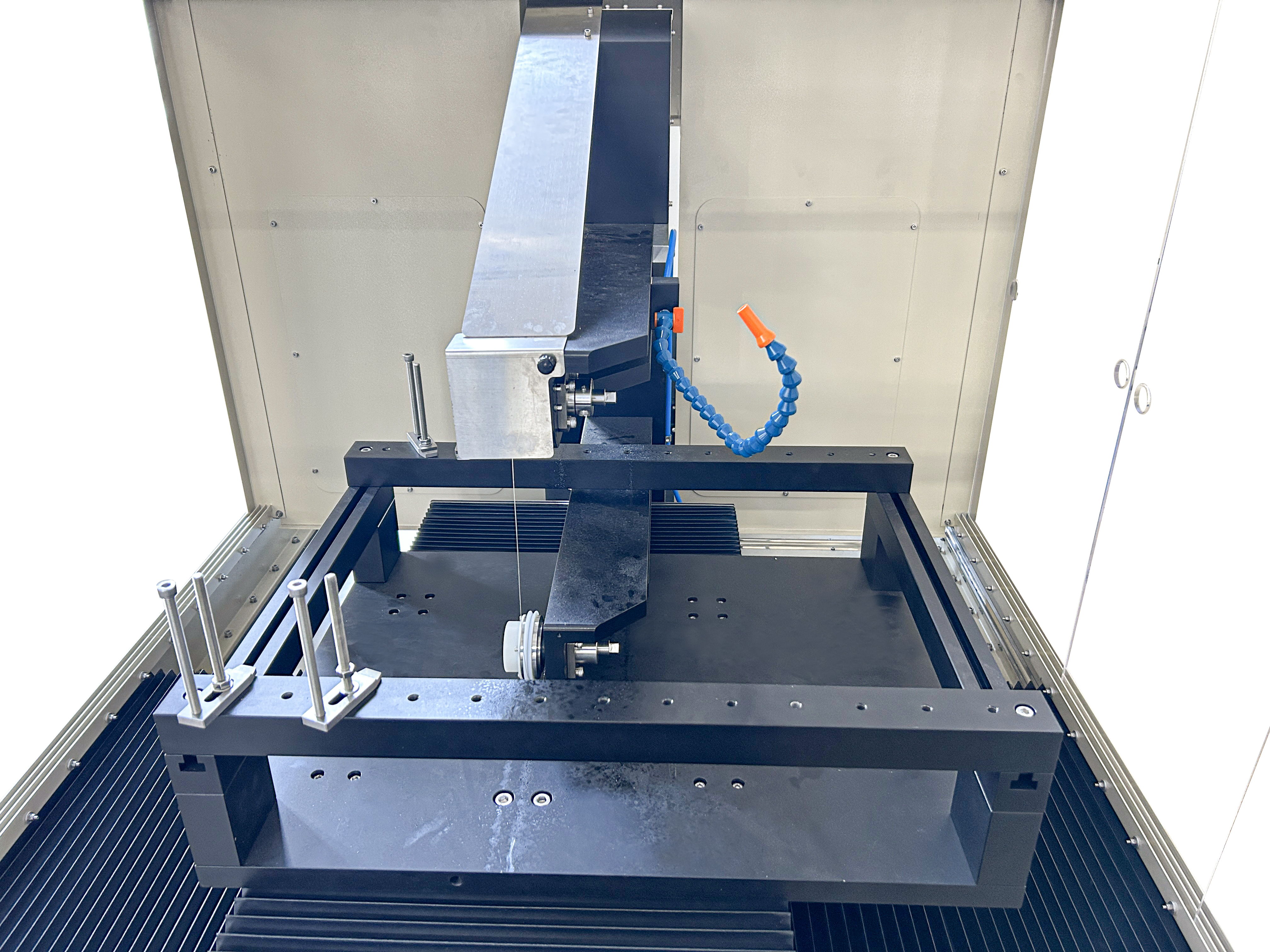

2024-07-27 16:09Recently, our company launched an advanced equipment Diamond Wire Saw For Cutting Various Shapes Max.400mm Square, which is specially designed for precise cutting of curved shapes. This cutting machine has excellent special-shaped cutting ability and a wide range of applications. In the field of material processing, it can effectively help enterprises solve the problem of special-shaped cutting of difficult-to-process materials.

Diamond Wire Saw For Cutting Various Shapes Max.400mm Square uses diamond wire technology to specifically cut non-metallic materials for special-shaped cutting. It sets the cutting shape through computer drawing software, and then the diamond wire moves accurately along the preset path to cut out various complex two-dimensional graphics, such as circles, I-shaped, airplane shapes, ovals, sectors, and various symmetrical and asymmetrical graphics. Not only can it cut thin sheets of materials, but also thicker materials. This technological breakthrough not only solves the problem of special-shaped cutting that is difficult to handle with traditional cutting methods, but also greatly improves processing efficiency and precision.

Diamond Wire Saw For Cutting Various Shapes Max.400mm Square has broad application prospects in material processing. It can not only cut hard and brittle materials such as ceramics, crystals, and glass, such as alumina ceramics, zinc oxide ceramics, zirconium oxide ceramics, graphite, silicon crystals, sapphire, etc., but also can efficiently process metals, composite materials, rocks, thermoelectric materials, infrared optical materials, and biomedical materials. Therefore, in many fields such as material science research, semiconductor manufacturing, geological exploration, and biomedical engineering, has high application value.

Diamond Wire Saw For Cutting Various Shapes Max.400mm Square has high cutting quality and stability. The cut sample has high dimensional accuracy and good surface condition, which is very suitable for occasions with strict requirements on cutting accuracy and surface quality. At the same time, it also adopts an advanced tensioning system and adjustment mechanism, which can keep the cutting wire in a stable tension state during long-term use, avoiding cutting quality problems caused by excessive or insufficient tension.

Shenyang Kejing Automation Equipment Co., Ltd. was established in May 2000. To date, we have hundreds of products covering the fields of material cutting, grinding, polishing, coating, mixing, rolling, sintering, analysis and related consumables, which can meet the full needs of preparation and analysis of crystals, ceramics, glass, petrography, mineral samples, metal materials, refractory materials and composite materials. Customers in need can contact us and welcome cooperation.