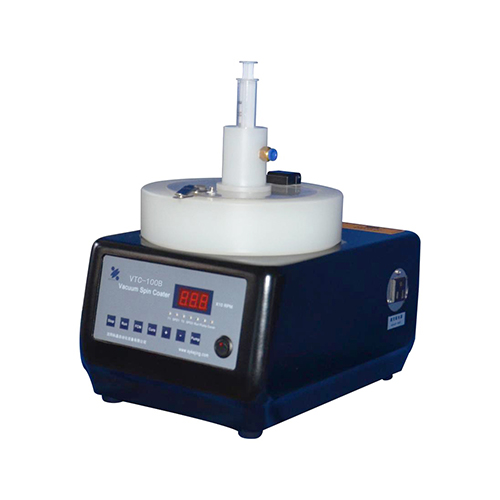

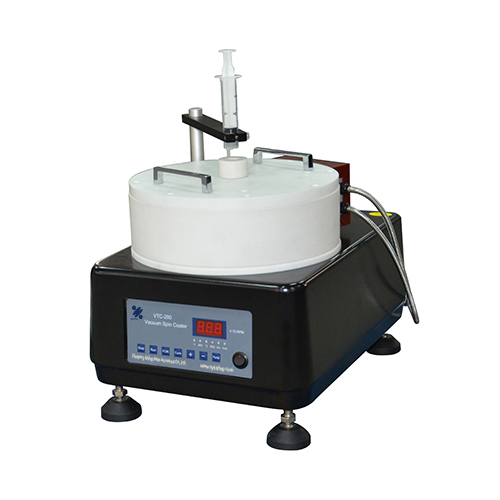

Vacuumable And Atmospher Controlled Spin Coater

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 10 working days

Supply capacity 50 sets

VTC-200PV Vacuum Spin Coater is suitable for semiconductor process, crystal, optical disc, plate making and surface coating, etc. The chamber of VTC-200PV vacuum spin coater can be vacuumized to coat the sample under completely vacuum condition, which is suitable for film materials that are easily oxidized and deteriorated in air. A clamp is used to fix the sample when the chamber is vacuumized. The equipment can store 12 sets of programs, and each set contains 6 running stages.

Main Features

1. The equipment can store 12 sets of programs, and each set contains 6 running stages. The setting range of the acceleration and deceleration rate for each stage: 100rpm/s-2000rpm/s, time range for each stage: 0-60s

2. The sample is fixed by means of vacuum adsorption and it can also be fixed by means of bonding or clamping, which is easy to operate.

3. The degree of vacuum can reach -0.08MPa.

4. Samples can be easily centered using the positioning tool to reduce vibration or fly-outs caused by misalignment.

5. Different chucks can be used according to sample specifications, and the replacement is convenient and simple.

6. A 24V brushless DC motor is adopted and it has the advantages of high reliability, strong adaptability, simple repair and maintenance, low noise, small vibration, stable operation, fast and stable startup, stable operation after acceleration, to ensure the consistency and uniformity of coating thickness.

7. The oilless parallel-bar vacuum pump is used when the sample is fixed by means of vacuum absorption, and it has the advantages of small size, simple structure, easy operation, convenient maintenance, and no environmental pollution.

8. Coating can be carried out in an inert gas atmosphere (such as Ar, N2).

9. When coating is performed under vacuum condition, the sample substrate is fixed by means of bonding or clamping.

10. The chamber is made of PP material with longer service life to improve the resistance abilities of chemical corrosion and excellent stress crack, and the machine body adopts cast aluminum structure, which is durable and light in weight.

11. English operating system

12. It has the function of open-cover protection. When the top cover is opened during the coating process or at the end of the coating, the machine immediately decelerates rapidly until it stops.

13. The controller adopts a control box with LCD numerical display, which is more intuitive and reliable.

Technical Parameters

Product Name | VTC-200PV Vacuum Spin Coater |

Product Model | VTC-200PV |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong earthquake source and corrosive gas around the equipment. 3. Water: The equipment is equipped with a sewage outlet 4. Electricity: Single phase: AC220V 50Hz National standard three-pole socket 10A must be well grounded 5. Gas: Vacuum negative pressure (vacuum pump) exhaust flow rate is not less than 70L/M (the equipment can pass protective inert gas) 6. Workbench: It is recommended to be 1500X600X700mm and bear a load of more than 100KG (solid cement platform is better) 7. Ventilation device: No special requirements |

Main Parameters (Specification) | 1. Power supply interface: Power socket with insurance: AC220V 50Hz, insurance tube specification is 10A, φ5×20mm (this device supports AC110V50/60Hz product customization) 2. Total power: ≤150W (excluding external vacuum pump) 3. Coating host cavity (material): polypropylene 4. Sample tray (chuck + suction cup): chuck type sample tray: Φ100 polypropylene vacuum suction cup: 1 5. Operation mode: 12 sets of programs can be stored, each set of programs contains 6 operation stages 6. Coating speed: 500rpm-6000rpm 7. Acceleration and deceleration rate: Each acceleration and deceleration setting range: 100 rpm —2000 rpm 8. Coating time: Each time range: 0-60s 9. Speed stability: ±1% 10. Control mode: PCB single chip microcomputer button control LMC LCD display 11. Oil-free vacuum pump (sampling vacuum): Model: AP-1400C/V Linked with the host Power supply: AC220V 50/60Hz 2A 0.45KW Ultimate vacuum: -0.0933MPa Rate: 150L/min 12. Mechanical vacuum pump (vacuuming the coating chamber): Model: VRD-8 Independent power supply: AC220V 50Hz 2.5A 0.4KW Ultimate pressure: 5X10-²Pa |

Standard Accessories

No. | name | qty | picture |

1 | Vacuum Chuck (φ100mm) | 1 pcs | |

2 | Clamping Plate 2”, 3”, 4” | 1 pcs | |

3 | Central Positioner/Locator (including 4 positioning studs) | 1 pcs | |

4 | Epoxy Injector/Syringe | 1 pcs |

|

5 | Oilless Vacuum Pump | 1 pcs | |

6 | Double-Click Rotary Vane Vacuum Pump VRD-8 | 1 pcs |

Optional Accessories

No. | name | functional type | picture |

1 | Vacuum Chuck of other specifications | (optional) |

|

2 | Pipette (made in China) | (optional) |

|

3 | Pipette (imported) | (optional) |

|

4 | VRD-16 Mechanical Pump | (optional) |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics