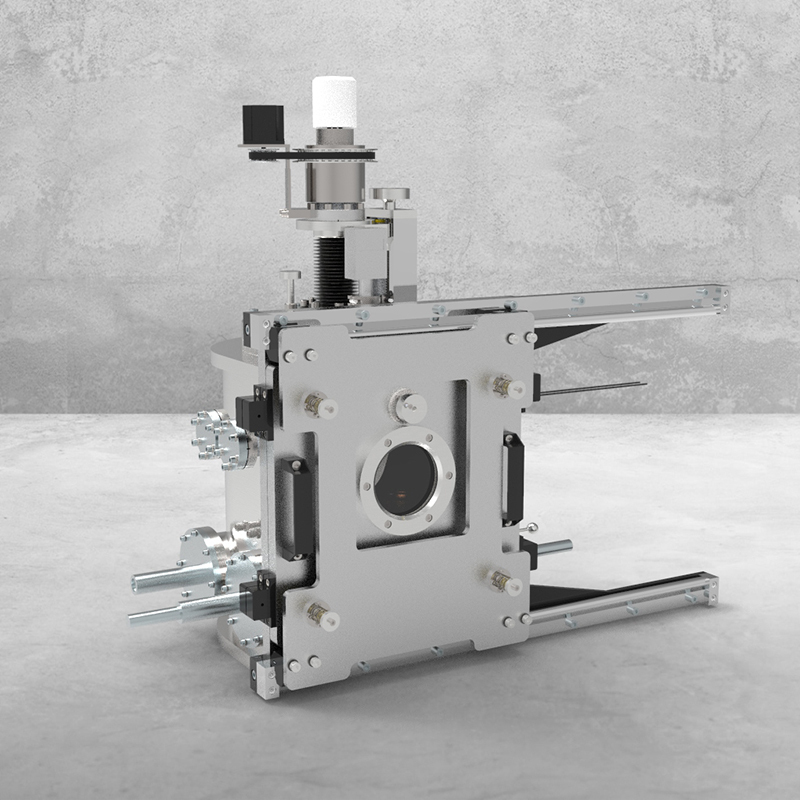

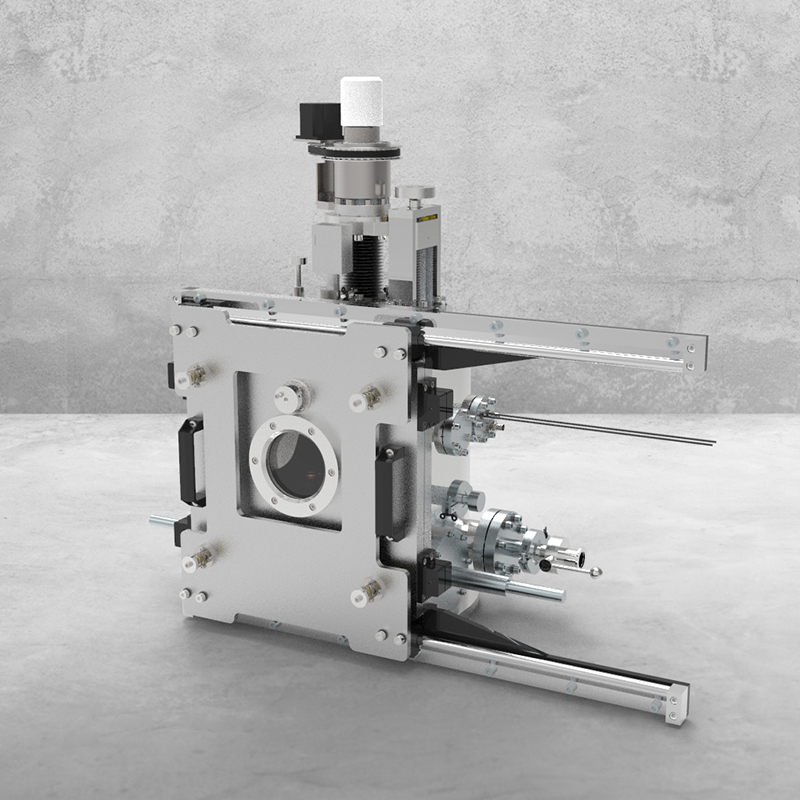

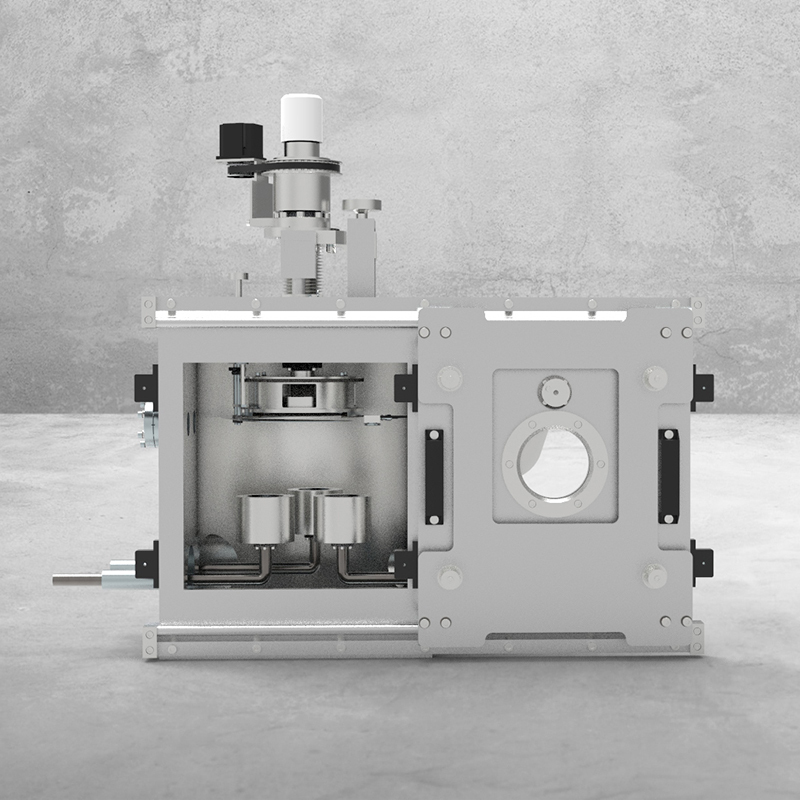

Three Targets Magnetron Sputtering Coater for Coating Substrates and Wafers

1. The thin film battery preparation system with glove box is equipped with three target guns, and a matching rf power supply can be connected to any target head through a conversion switch, which is used for sputtering coating of various target materials (the target gun can be replaced at any time according to customer needs).

2. The thin film battery preparation system with glove box can prepare a variety of thin films and is widely used.

3. The thin film battery preparation system with glove box is small in size and very easy to operate.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of compact plasma sputtering coater:

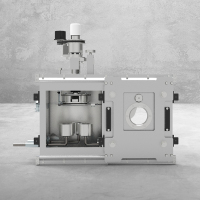

VGB-600-3HD Thin film battery preparation system with glove box can be used for experimental operation in the glove box, and is used to prepare single-layer or multi-layer ferroelectric thin films, conductive thin films, alloy thin films, semiconductor thin films, ceramic thin films, dielectric thin films, optical thin films, oxide thin films, hard thin films, polytetrafluoroethylene thin films, etc. The compact plasma sputtering coater is equipped with three target guns, and a matching RF power supply can be connected to any target head through a conversion switch, which is used for sputtering coating of various target materials. Compared with similar equipment, the compact plasma sputtering coater is not only widely used, but also has the advantages of small size and easy operation. It is an ideal equipment for laboratory preparation of material films. The compact plasma sputtering coater is particularly suitable for laboratory research on thin film batteries, solid electrolytes and OLEDs. Compared with ordinary magnetron sputtering, it can be used for coating experiments on Li targets and lithium-based material targets. It is an ideal equipment for laboratory coating experiments in the new energy industry.

Advantages of three targets RF magnetron sputtering coater:

1.Three targets RF magnetron sputtering coater adopts modular design, and the vacuum chamber, vacuum pump group, and control power supply are split and can be adjusted according to the actual needs of users.

2.Three targets RF magnetron sputtering coater can select power supply according to the actual needs of users. One power supply can control multiple target guns, or multiple power supplies can control a single target gun (optional).

3.Three targets RF magnetron sputtering coater can be used for experimental operation in the glove box, and various types of easily oxidized target materials can be replaced for coating experiments.

Technical parameters of compact plasma sputtering coater:

| Product name | VGB-600-3HD Compact Plasma Sputtering Coater |

| Product model | VGB-600-3HD |

| Main parameters | Three-target magnetron sputtering part: 1. Power supply voltage: 220V 50Hz. 2. Total power: 2.5KW. 3. Ultimate vacuum: < E-6mbar (can reach E-3mbar when used with our company's mechanical pump equipment). 4. Working temperature: RT-500℃, accuracy ±1℃ (temperature can be increased according to actual needs). 5. Number of target guns: 3. 6. Target gun cooling method: water cooling. 7. Target size: Ø2″, thickness 0.1mm-5mm (thickness varies due to different target materials). 8. Sputtering power: 300W (RF)/500W (DC). 9. Sample carrier: Ø140mm. 10. Sample carrier speed: adjustable within 1rpm-20rpm. 11. Protective gas: inert gas such as Ar and N2. 12. Inlet gas path: Mass flow meter controls 2 inlet paths, one flow is 100 SCCM, and the other flow is 200 SCCM. |

Glove box part: 1. Power supply: single-phase AC110V-220V 50Hz/60Hz. 2. Shell material: 304 stainless steel. 3. Glove box chamber: 1220mm×760mm×900mm. 4. Pre-stage chamber: There are 2 pre-stage chambers, the large pre-stage chamber is Ø360mm×600mm, and the small pre-stage chamber is Ø150mm×300mm. 5. Chamber environment: water content <1ppm (20℃, 1atm), oxygen content <1ppm (20℃, 1atm). 6. Working gas: inert gas such as N2, Ar, He. 7. Control gas: compressed air or inert gas. 8. Reduction gas: a mixture of working gas and H2 (if the purification system only has the function of removing water, the reduction gas is the same as the working gas). 9. Gas purification system: German BASF deoxidizing materials, American UOP water-absorbing materials, automatic control of the purification system regeneration process, automatic dehydration and deoxidation functions, which can maintain the gas purity at water <1ppm and oxygen <1ppm for a long time. 10. Pressure control system: The cavity air pressure can be automatically controlled by the PLC touch screen with a control accuracy of ±1Pa, and can also be manually controlled by the foot switch. 11. Filter system: Filters are installed at the inlet and outlet ends, with a filtration accuracy of 0.3μm. 12. Control system: SIEMENS color touch screen (6 inches), PLC control system, Chinese and English bilingual switchable; Water probe adopts American GE brand, 0-1000ppm touch screen display, accuracy 0.1ppm; Oxygen transmitter adopts American AII brand, 0-1000ppm touch screen display, accuracy 0.1ppm; Pressure sensor adopts American setra brand, -2500-2500Pa touch screen display, accuracy ±1Pa; 13. Vacuum pump: British EDWARDS brand, pumping speed 8.4m3/h-12m3/h. 14. Gloves: American NORTH brand butyl synthetic rubber. 15. Lighting system: Philips brand fluorescent tube. | |

| Product specifications | Three-target magnetron sputtering part: 950mm×460mm×810mm. Glove box part: 2300mm×1500mm×1900mm. |

Quality commitment of three targets RF magnetron sputtering coater:

Our company guarantees that the compact plasma sputtering coater provided is new and unused, fully meets the quality, specifications and performance requirements stipulated in the contract, and our thin film battery preparation system with glove box can operate normally under correct installation, correct use and maintenance conditions and within the service life.

Warranty:

One-year limited warranty, lifetime support (excluding parts rusted due to improper storage conditions)

Our services:

Our products are recognized by many customers for their excellent performance, stable quality and long-term durability. We have a professional technical team that can provide customers with a full range of service support such as product selection, installation and commissioning, and operation training. No matter what problems you encounter during use, we will strive to provide you with timely and effective solutions to make your production line run efficiently and stably.

About us:

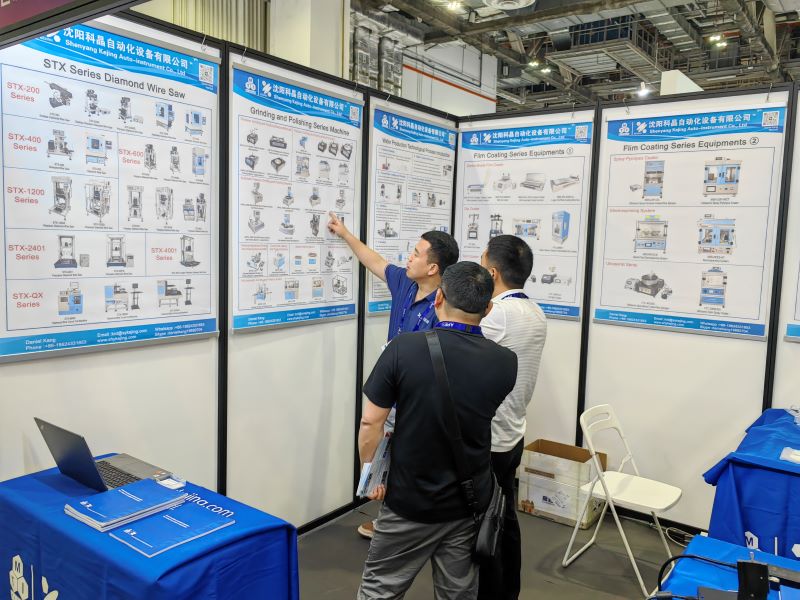

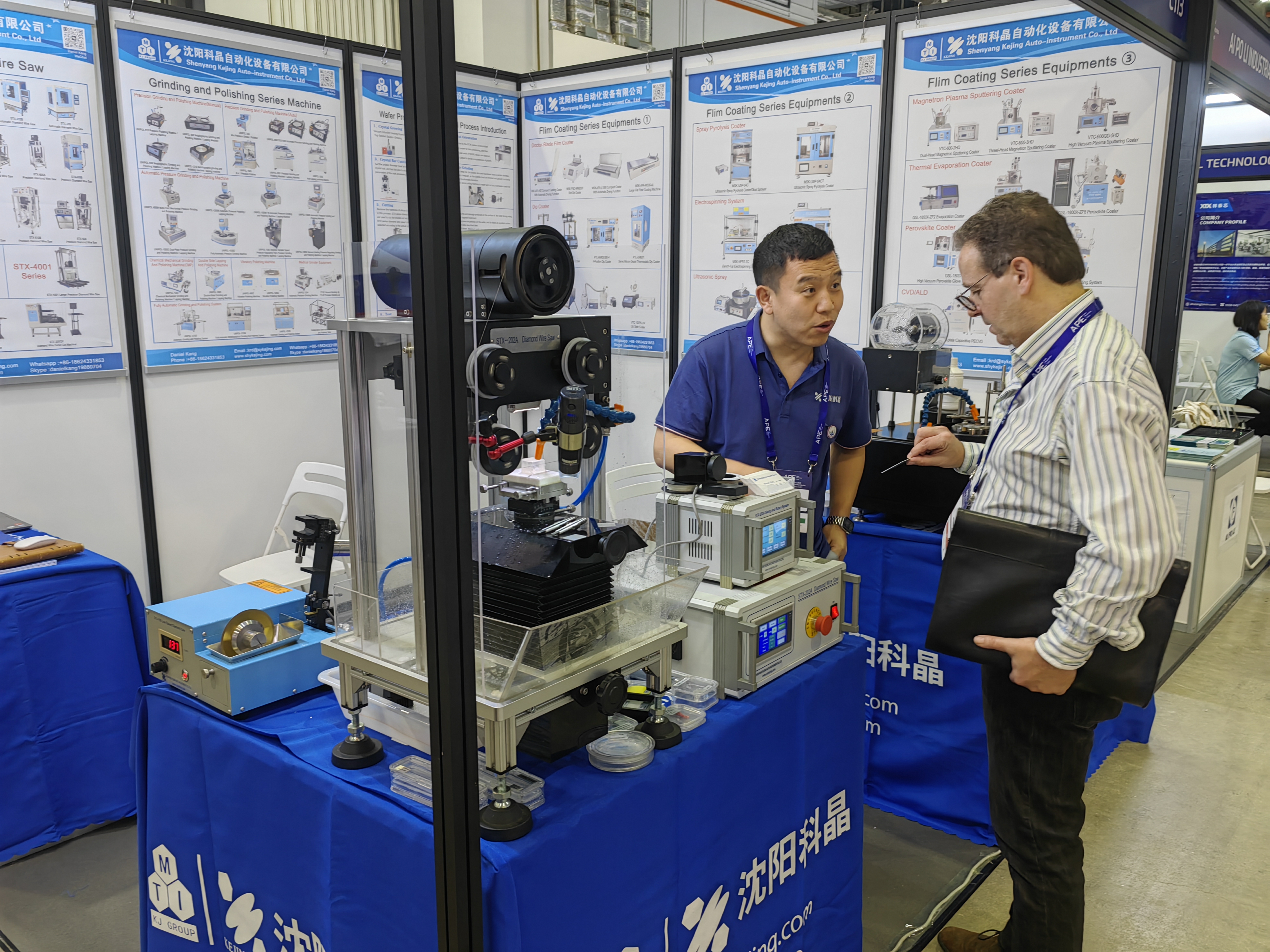

Not long ago, our district Singapore participated in the Asia Photonics Expo (APE 2025), where we displayed our grinding and polishing machines, coating machines and other products. After learning about the products in detail, many customers praised our equipment and expressed their desire to cooperate with us.