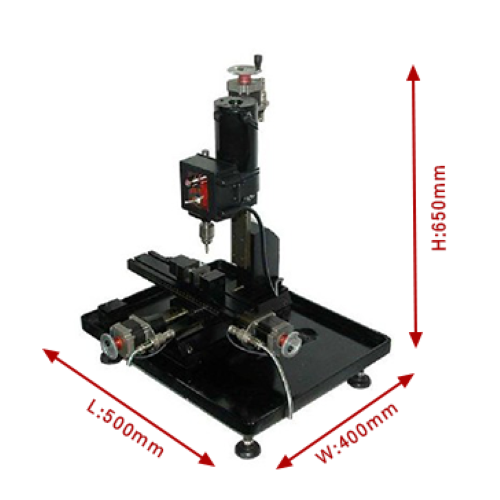

Manual Precision Micro Milling Machine

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 10 working days

Supply capacity 50 sets

1. Precision micro milling machine supports personalized model manufacturing and is widely used in DIY and artistic creation.

2. Precision micro milling machine is small in size and light in weight, saving laboratory or workspace and convenient for flexible movement and operation.

3. Mini CNC milling machine supports both manual control and automatic CNC control through the control box.

Introduction of miniature milling machine:

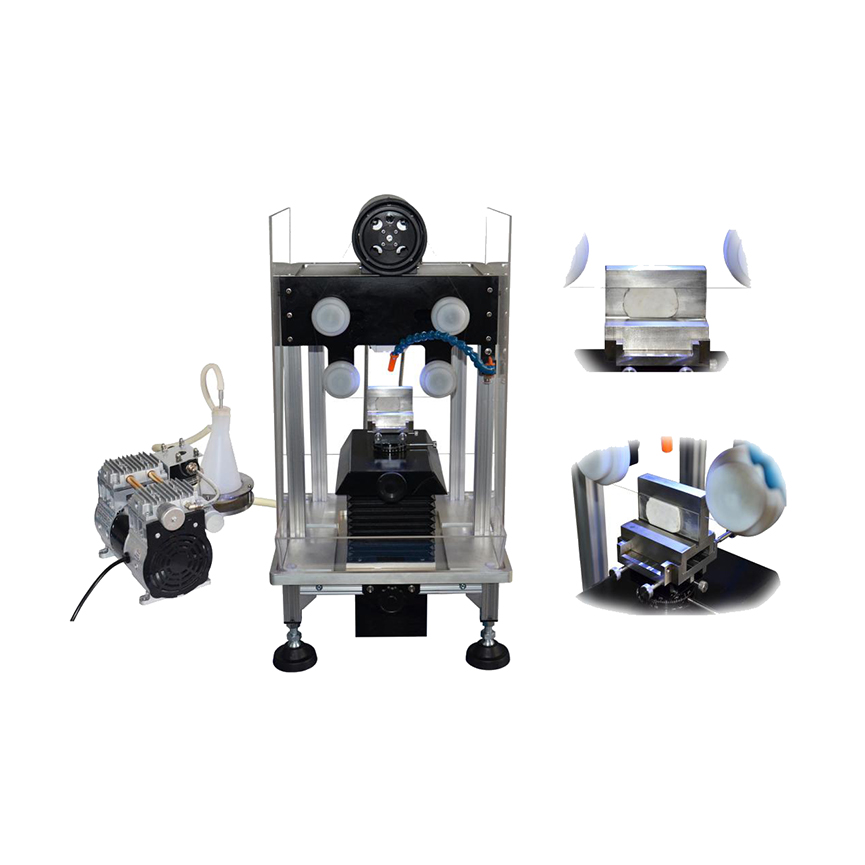

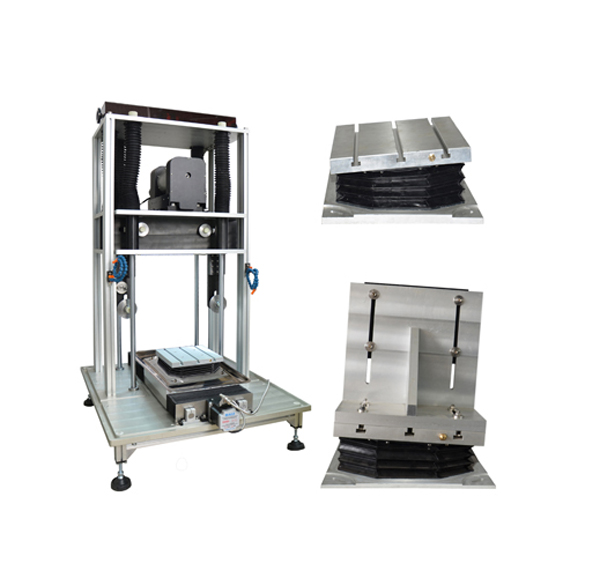

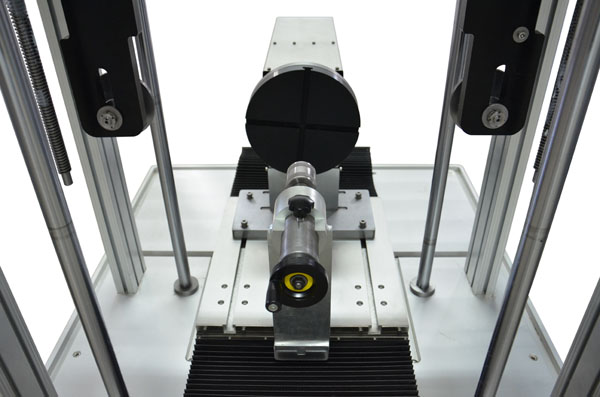

ATX-2010 CNC precision micro milling machine is a manually controlled precision milling equipment. Miniature milling machine has the advantages of small size, light weight and high milling precision. Miniature milling machine can precisely process metal, ceramics, glass, wood products, plastics, organic glass and other materials. Miniature milling machine is suitable for teaching, scientific research, student internships in majors such as machinery, automation, numerical control, industrial design, etc. In colleges and universities and scientific research institutes, as well as for enterprises to carry out R&D, small-scale production, DIY professional model manufacturing, etc. Mini CNC milling machine mainly performs operations such as drilling and grooving on workpiece materials, and mainly performs linear milling on sample materials.

Advantages of mini CNC milling machine:

1.Mini CNC milling machine has high-precision milling function and can process metal, ceramic, glass and other materials.

2.Micro precision milling machine can be used for drilling, grooving, milling and other operations, especially suitable for linear precision milling of sample materials.

3.Micro precision milling machine can be quickly used even by users without rich experience, suitable for both beginners and professionals.

Technical parameters of micro precision milling machine:

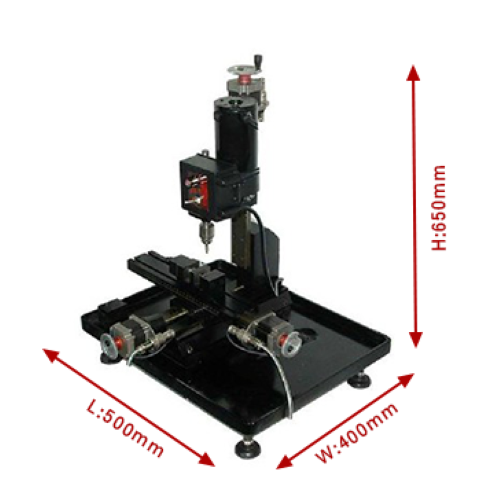

Product name | ATX-2010 CNC Micro Precision Milling Machine | |

Product model | ATX-2010 | |

| Main parameters | 1. X-axis travel: 200mm. | |

2. Y-axis travel: 75mm. | ||

3. Z-axis travel: 150mm. | ||

4. Main motor speed: 20rpm-2800rpm. | ||

| 5. Drilling diameter: Ø6.5mm (max). | ||

6. Product specifications: Size: 500mm×400mm×650mm. Weight: 25kg. |  | |

Standard accessories:

| NO. | Name | Qty | Picture |

| 1 | Bench vise | 1 piece | -- |

| 2 | Drill chuck | 1 piece | -- |

| 3 | Milling cutter | 1 set | -- |

Optional accessories:

| NO. | Name | Function category | Picture |

| 1 | Milling cutter | (optional) | -- |

| 2 | Vises | (optional) | -- |

| 3 | Special tooling fixtures | (optional) | -- |

About us:

Our company focuses on the research and development and production of material analysis equipment. With advanced technology and rich experience, we are committed to providing high-quality material preparation and analysis equipment for universities, research institutes and manufacturing companies. Our production process covers the complete process from product design, manufacturing, quality inspection to after-sales service, so that the products have excellent performance and reliability. In the development process of the company, we always adhere to innovation-driven, customer-oriented, continuously improve product quality and technical level, and strive to provide customers with efficient and professional services.