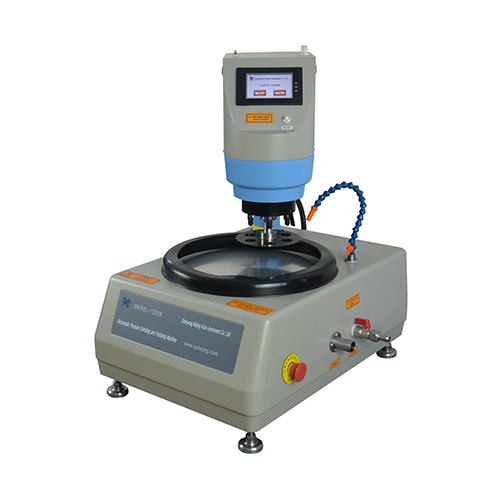

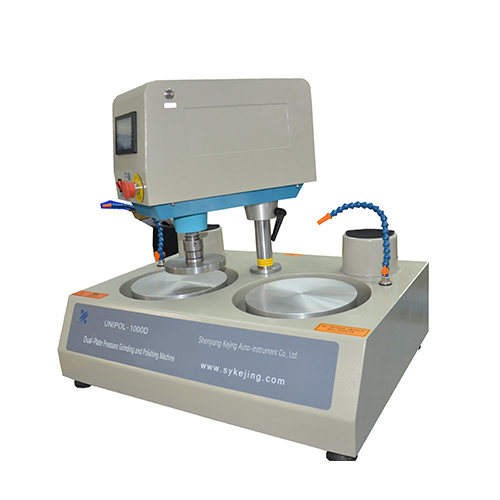

Lapping And Polishing Machine With Stepless Speed Pressure

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 44 working days

Supply capacity 50 sets

1. The stepless variable speed pressure regulating polishing machine can prepare metallographic samples in about 15-20 minutes, which is suitable for large steel plants and high-frequency sample preparation.

2. The stepless variable speed pressure regulating polishing machine is equipped with a Φ320mm grinding and polishing disc, a Φ160mm flat disc/peach-shaped hole disc, and a Φ110mm gravity sample loading disc.

3. The stepless variable speed pressure regulating polishing machine has functions that can improve the accuracy of grinding and polishing.

Introduction of stepless high precision grinding and polishing machine:

UNIPOL-1260 stepless high precision grinding and polishing machine can be used for grinding and polishing of artificial crystals, ceramics, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), quartz glass, rocks and other materials. It is particularly suitable for the preparation of metallographic samples, as well as the grinding and polishing of hard and brittle materials such as white sapphire and sapphire. It takes about 15min-20min to prepare general metallographic samples with stepless high precision grinding and polishing machine, which is especially suitable for large steel plants and units that prepare a large number of metallographic samples.

Main features of stepless variable speed lapping and polishing machine:

1. The sample is fixed on a special carrier plate, which can be easily installed using a quick-change chuck. An elastic coupling is provided on the carrier plate fixing seat to prevent the sample from being damaged by the impact caused by the instantaneous contact with the grinding and polishing disc.

2. When the sample contacts the grinding and polishing disc, the cylinder cross arm begins to apply pressure. The pressure of the stepless variable speed lapping and polishing machine can be preset, but because it adopts a stepless adjustment method, it can also be adjusted at any time during operation. The actual pressure limit can reach 0.5mpa.

3. The grinding and polishing disc speed and the carrier disc speed can be adjusted steplessly within their range, so the stepless variable speed lapping and polishing machine can be preset and adjusted at any time.

4. The grinding and polishing time can be set arbitrarily within the range of 0-24h. The stepless variable speed lapping and polishing machine can realize automatic grinding and polishing, and automatically stop when the time comes.

5. The core components of the stepless high precision grinding and polishing machine are made of stainless steel with precision machining.

6. The pneumatic and electrical parts of the stepless high precision grinding and polishing machine are all products of the latest international technology, with reliable performance and durability.

7. The frame structure is welded with high-quality steel, with high strength and good rigidity.

Technical parameters:

Product Name | UNIPOL-1260 Stepless Variable Speed Pressure Regulating High-Precision Grinding and Polishing Machine / Lapping Machine |

Product Model | UNIPOL-1260 |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong earthquake source and corrosive gas around the equipment. 3. Power supply: single phase: AC220V 50Hz national standard three-pole socket 16A (the socket must have a good safety protection grounding wire). 4. Cooling water: The equipment is equipped with an inlet and a drain, which can be connected to a circulating stirring pump for grinding and polishing dripping, or connected to tap water and drainage pipelines for auxiliary use of abrasive addition. 5. Air source: Air source pressure: ≥0.6MPa (6kgf/cm2); Flow rate: >20L/min air compressor or other compressed air source device. 6. Ventilation device: Good ventilation environment, no special ventilation device requirements. 7. Auxiliary equipment (purchased separately). Recommendations: 1. HEATER-3040 or 250 heating platform. 2. QYJ-1 card sample machine. 3. XQ-2B metallographic sample mounting machine. 4. SZKD-series dripper. 5. YJXZ-12 stirring circulation pump. |

Main Parameters (Specification) | 1. Equipment power supply port: AC220V, 50Hz 16A. 2. Total power: 1.3KW (MAX). 3. Grinding and polishing disc diameter: Cast iron grinding disc/cast aluminum polishing flat disc: Φ320mm. 4. Quick card sample loading diameter: Flat disc/peach-shaped hole disc: Φ160mm. 5. Gravity sample loading disc diameter: Φ110mm (flat surface). 6. Upper disc main drive motor: DC110V, 185W (reduction motor). 7. Lower disc main drive motor: AC220V, 1.1KW (frequency conversion). 8. Upper sample loading disc speed: 10-250rpm (speed adjustable). 9. Lower grinding and polishing disc speed: 5-300rpm (speed adjustment). 10. Working pressure range: Setting range: 0-0.4MPa. 11. Working time setting: M: 0-59, H: 0-999. 12. Control method: Combination button + Touch screen. |

Product Dimension and Weight | Dimension: L550×W940×H1440mm. Weight: ≈250kg.

Notes: 1. The power supply of stepless variable speed pressure regulating polishing machine is the national standard single-phase ac 220V 50Hz. The actual power supply parameters are subject to the label attached to the back of the product. 2. Stepless variable speed lapping and polishing machine can customize various grinding and polishing discs, special sample trays, fixtures, special parts, etc. According to user requirements. 3. The external "air compressor" requires the control pressure value to be within the range of 0.6~0.8MPa. |

Standard accessories:

No. | Name | Qty | Picture |

1 | Cast Iron Polishing Plate | 1 pcs | |

2 | Cast Aluminum Polishing Plate | 1 pcs | |

3 | Flat Sample Holding Plate | 1 pcs | |

4 | Peach-Shape Hole Sample Plate | 1 pcs | |

5 | Condition Ring | 1 pcs |

|

6 | Polishing Pad (Nubuck Leather, Synthetic Leather, Polyurethane) | 1 pcs each |

|

7 | Corundum Grinding Powder

| 0.5kg |

|

8 | Wax Bar | 4 pcs |

|

Optional accessories:

No. | Name | Functional type | Picture |

1 | YZXZ-12 Stirring Circulation Pump | (optional) | |

2 | QYJ-1 Sample Fixture | (optional) | |

3 | XQ-2B Metallographic Sample Mounting Press | (optional) | |

4 | SKZD-5 Slurry Feeder | (optional) |

|

5 | Mute Oilless Air Compressor | (optional) |

|

Warranty:

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

Shenyang Kejing's factory is located in Shenyang City, Northeast China, covering an area of 14,000 square meters. It integrates R&D, design, production, testing, packaging and after-sales service, and has a complete production chain. The production area is 2,818 square meters, with advanced equipment to efficiently produce high-quality products; the warehouse area is 2,908 square meters, ensuring adequate storage of finished products and raw materials and supporting efficient logistics management. Welcome to visit our factory!