Infrared Drying Flatbed Coater Machine For Lab

Brand Shenyang Kejing

Product origin Shenyang, Liaoning

Delivery time 10 working days

Supply capacity 50 sets

1. The laboratory electric heat film coating machine uses a precision stepping gearbox motor, and the PLC accurately controls the coating speed.

2. The laboratory electric heat film coating machine uses a fully stainless steel roller scraper, which effectively reduces the friction resistance between the scraper and the vacuum suction cup when it moves.

3. The waste collection box placed at the bottom of the left side of the vacuum suction plate can collect excess coating materials to ensure the cleanliness of the laboratory electric heat film coating machine itself and the surrounding area.

Introduction of sheet film coater with vacuum chuck:

MSK-AFA-E500-AL sheet film coater with vacuum chuck is mainly used for coating liquid or colloidal films in the laboratory. Sheet film coater with vacuum chuck uses a precision stepping gearbox motor to accurately control the coating speed, so as to achieve the purpose of uniformly advancing the scraper for coating. The roller scraper is made of all stainless steel, which effectively reduces the friction resistance between the scraper and the vacuum suction cup when the scraper moves, and can improve the consistency and uniformity of the coating. The equipment uses bottom vacuum to absorb the sample. The equipment is equipped with a scraper limiter, which can adjust the length of the coated film at will. The roller scraper stops automatically after reaching the limit; automatic film coater with adjustable doctor blade is equipped with a top infrared baking function, and the baking temperature can reach up to 120℃, thereby accelerating the drying speed of the coating. This automatic film coater with adjustable doctor blade is specially designed to prepare various films by coating, such as lithium battery electrode films, various ceramic films and polymer films.

Advantages of automatic film coater with adjustable doctor blade:

1. Automatic film coater with adjustable doctor blade has top infrared heating function, heating temperature is 120℃ (bottom heating function and higher heating temperature can be customized).

2. Sheet film coater with vacuum chuck can be used with extrusion coating accessories for extrusion coating.

3. Laboratory electric heat film coating machine is equipped with laser cover opening protection function, which automatically stops heating the upper cover after sensing the cover opening.

Technical specifications of sheet film coater with vacuum chuck:

| Product name | MSK-AFA-E500-AL Infrared Drying Flatbed Coater Machine |

| Product model | MSK-AFA-E500-AL |

| Installation conditions | Operating environment: Humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 1. Water: Not required. 2. Electricity: AC220V. 3. Gas: Vacuum negative pressure (vacuum pump). 4. Workbench: 1500×800×500mm is recommended; load-bearing capacity is more than 160KG. 5. Ventilation device: No special requirements. |

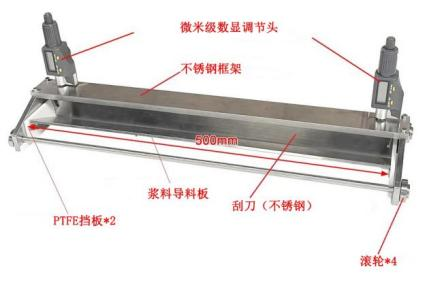

| Main parameters | 1. Power supply interface: AC220V (the actual value is subject to the equipment label). 2. Total power: ≤3000W. 3. Vacuum suction cup dimensions (length × width): 1190mm × 550mm. 4. Vacuum adsorption dimensions (length × width): 1000mm × 500mm. 5. Vacuum suction cup coating, applicable coating thickness ≥ 0.3mm. 6. Coating speed: 500-5000mm/min. 7. Coating length: 10-1000mm (length adjustable). 8. Infrared cover heating temperature 120℃. 9. Rolling scraper: Se-KTQ-500. Standard coating width: 500mm. Film thickness adjustment range: 0-5000um. PTFE baffle to avoid slurry leakage. The scraper frame is equipped with 4 rollers to facilitate the movement of the film maker. Equipped with 2 digital micrometer heads with an adjustment accuracy of 3um.

10. Optional extrusion coating head Se-KTQ-500SD: (For the preparation of catalyst electrode coating in low-temperature fuel cells, gas diffusion porous carbon (GDL) is usually used as the substrate for coating. At this time, scraper coating is not suitable, and extrusion coating must be used (the extrusion head is at a certain distance from the rough porous substrate).

11. Overall dimensions (length × width × height): 1280mm × 620mm × 465mm.

|

About us:

Before the product leaves the factory, our staff will conduct comprehensive testing to ensure the accuracy and stability of the product. At the same time, we also have a professional after-sales service team. If you have any questions about the product, our team will answer you in time, so that your equipment can run stably for a long time.