High Vacuum Magnetron Sputtering Coater

1. The ultimate vacuum of the sputtering coater with single head can reach 8.0X10-5Pa.

2. The sputtering coater with single head is equipped with 1 evaporation heating boat, 2 beam source furnace stations (1 beam source furnace is standard), 1 set of flow meters (one set of argon gas) with φ150 glass observation window.

3. After you receive the sputtering coater with single head, we will also provide comprehensive after-sales services, such as remote guidance.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of high vacuum magnetron sputtering coater:

VTC-1HD-ZF2 High vacuum magnetron sputtering coater is a multifunctional high vacuum coating equipment, including a single target magnetron sputtering instrument. High vacuum magnetron sputtering coater can be used to prepare single or multi-layer ferroelectric films, conductive films, alloy films, semiconductor films, ceramic films, dielectric films, optical films, oxide films, hard films, polytetrafluoroethylene films, etc.

Advantages of magnetron plasma sputtering coater:

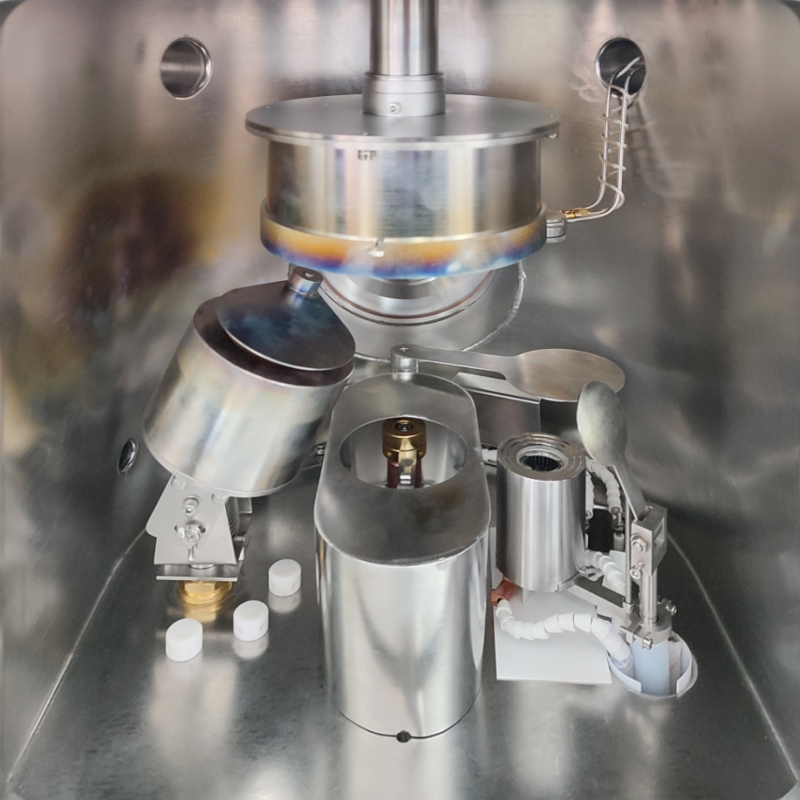

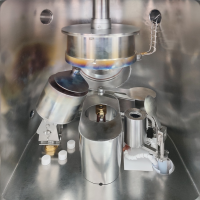

1. Magnetron plasma sputtering coater is equipped with a vapor deposition heating boat, which is particularly suitable for vapor deposition of metal films that are sensitive to oxygen (such as Ti, Al, Au, etc.). There is a rotatable baffle above the heating boat of Magnetron plasma sputtering coater, 2 beam source furnace stations (1 beam source furnace is standard). 1 set of flow meters (one set of argon gas) with φ150 glass observation window.

2. Scope of application of Magnetron plasma sputtering coater: device preparation of perovskite materials, two-dimensional materials, photovoltaic solar cells, etc.

3.3. Sputtering coater with single head power input: AC220V/50Hz. Power <3.5KW.

Technical parameters of magnetron plasma sputtering coater:

| Product name | VTC-1HD-ZF2 High Vacuum Magnetron Sputtering Coater |

| Product model | VTC-1HD-ZF2 |

| Main parameters | 1. Vacuum chamber: φ324X330 Ultimate vacuum 8.0X10-5Pa (molecular pump system) Leakage rate: 2.0x10-10Pa.m3/s Material is 304 stainless steel welding, electrochemical surface polishing treatment. The active part is sealed with a rubber seal ring, and the inactive part is sealed with a copper seal ring. The power transmission adopts magnetic coupling linkage. The vacuum chamber has a magnetic control target position, a set of evaporation electrodes (two), and 2 beam source furnace positions (standard 1 beam source furnace). One set of flow meters (one set of argon gas) with a φ150 glass observation window, and a C35 flange interface is reserved. |

2. Sputtering target head: 2 inches (φ50.8mm) Working vacuum: 10Pa~0.2Pa. Target material utilization rate: >35% (standard 3mm copper target, target surface vacuum 0.5Pa) MAX power: <240W (fully cooled) Insulation voltage: >2000V (with 1 500W DC power supply) | |

3. Resistance evaporation: Evaporation output voltage: AC 0-8V continuously adjustable. Limit evaporation current 200A. Limit evaporation power <1.6KW. Temperature is uncontrollable and unmeasurable. | |

4. Beam source furnace: Crucible capacity: 3CC. Heating temperature: room temperature to 800°C. Heating temperature can be measured, adjusted and controlled. Temperature control accuracy: ±0.5°C. Quartz crucible with baffle and thermocouple as standard. Power supply: 500W, 36V. | |

5. Sample stage: φ120. Temperature control: room temperature - 500°C. Speed: 1-20rpm. The sample stage can be raised and lowered manually, with a maximum adjustable stroke of 50mm. | |

6. EQ-TM106-1 film thickness meter. 1) Power supply: DC 5V (±10%), maximum current 400mA. 2) Frequency resolution: ±0.03Hz. 3) Film thickness resolution: 0.0136Å (aluminum). 4) Film thickness accuracy: ±0.5%, depending on process conditions, especially sensor position, material stress, temperature and density. 5) Measurement speed: 100ms-1s/time, adjustable. 6) Measuring range: 500000Å (aluminum). 7) Standard sensor crystal: 6MHz. 8) Computer interface: RS-232/485 serial interface (baud rate 1200, 2400, 4800, 9600, 19200, 38400 can be set, data bit: 8, stop bit: 1, check: none) 9) Analog output: 8-bit resolution, PWM pulse width modulation output (open collector or internal 5V output) 10) Working environment: temperature 0-50℃, humidity 5%-85%RH, no condensation. 11) Dimensions: 90mm×50mm×18mm. | |

| 7. The equipment is equipped with a chiller (KJ5000 model) as standard. Customers are required to provide their own chiller and deionized water or purified water. | |

| 8. Power input of the whole machine: AC220V/50Hz. Power <3.5KW. | |

9. Product specifications: Size: about 1300mm×660mm×1200mm. Weight: about 160 kg. |

About us:

We have advanced production equipment and a strict quality management system to ensure that every product meets international standards. Among them, our Sputtering coater with single head is particularly suitable for evaporating metal films that are sensitive to oxygen. It has stable performance and is widely used in the field of material research. Our R&D team continues to innovate, combining market demand and customer feedback to provide more accurate and efficient solutions. With many years of industry experience and technical accumulation, we have not only established a good reputation in the industry, but also won high recognition from many customers.