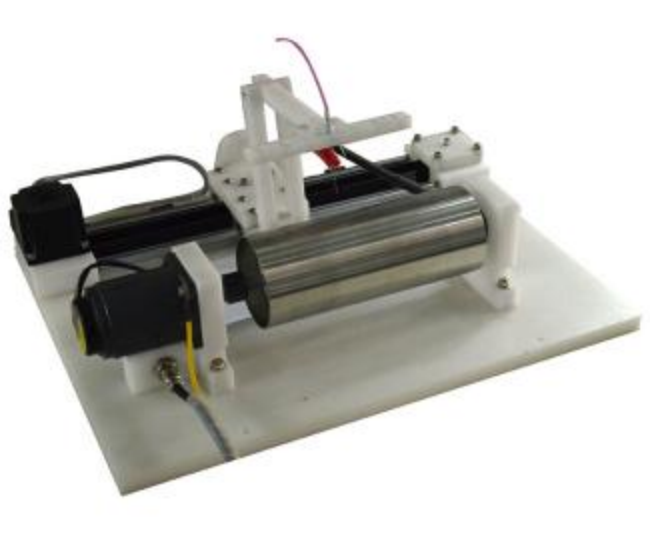

Desktop Nano-fiber Electrospinning Machine

1. The Nanofiber electrospinning machine is easy to operate and convenient to use.

2. Software controls various functions, and the Nanofiber electrospinning machine has the advantage of high precision.

3. The Nanofiber electrospinning machine uses a frame chassis, which is safer and more reliable during use.

- Shenyang Kejing

- Shenyang, Liaoning

- 22 working days

- 50 sets

- Information

Introduction of Desktop nano-fiber electrospinning unit with 2 collectors :

Electrospinning is a simple and effective processing technology that uses a high-voltage electric field to spin polymer solutions or melts into fine fibers with a scale of microns to nanometers, that is, polymer jet electrostatic stretching spinning. Since the fibers prepared by electrospinning are much finer than those prepared by traditional spinning methods, the diameter is generally tens to thousands of nanometers, and the interconnected pore nanofiber materials prepared by the electrospinning processing method have a large specific surface area, and many tiny secondary structures will be formed on the fiber surface, so they have strong adsorption and good filtration, barrier, adhesion and thermal insulation properties.

The main application areas of Lab nanofiber electrospinning machine: preparation of biopolymers, general polymers, and prepolymer nanofibers; preparation of polymer blend nanofibers; preparation of surfaces or films with nanopores, nanoparticles, and nanobead structures.

The main features of the Desktop nano-fiber electrospinning unit with 2 collectors:

1. Integrated operation.

The touch screen of the Lab nanofiber electrospinning machine is combined with an industrial-grade PLC to control all parameters, making the operation convenient and intuitive. Stable operation and high control accuracy.

A variety of wire collection modules can be replaced, and the control screen contains the control programs of various wire collection modules. The control modules can be switched through the main screen, which is convenient to use.

Different modules can be customized, and the software can be upgraded later.

2. The high-voltage power supply is controlled separately.

The Lab nanofiber electrospinning machine can adjust the high-voltage power supply through the knob, which can increase and decrease the voltage in real time, and is easy to operate.

Desktop nano-fiber electrospinning unit with 2 collectors has a breakdown protection function to protect the safety of experimental personnel.

Desktop nano-fiber electrospinning unit with 2 collectors has a high-voltage discharge device to ensure the personal safety of the operator after it is turned on.

3. Two sets of micro-injection pumps, safe, stable and flexible.

High-pressure resistant design, can be placed in the chassis for use to avoid high-pressure breakdown.

High-precision propulsion device, continuous feeding without interruption.

The needle and the syringe are connected by a hose, which is easy to use. The injection pump can be placed at any position in the box, which is easy to operate.

Two injection pumps can be used at the same time for coaxial spinning experiments.

The needle holder can adjust the angle at will, suitable for different spinning methods.

A variety of different needles can be selected

Equipped with conjugate spinning module and drum spinning module, suitable for different spinning forms

4. With temperature and humidity control system.

Lab nanofiber electrospinning machine adopts industrial-grade condensation dehumidification module, the dehumidification speed is fast

5. Profile frame chassis, safe and reliable.

The chassis is wrapped with PTFE, which has the advantages of high-voltage insulation and chemical corrosion resistance, ensuring the stability of the electrostatic field in the box.

The lighting system uses a high-brightness LED spinning observation lamp. The spinning observation lamp can observe the spinning process with the naked eye.

Technical Parameters of Lab nanofiber electrospinning machine:

Product name | MSK-NFES-3C-DZ01 Electrospinning Machine | |

Product model | MSK-NFES-3C-DZ01 | |

Main parameters | 1. Power supply: 220V 50Hz. 2. Positive high voltage power supply +30kV, negative high voltage power supply -30kV. 3. Heating function: RT-50℃ (infrared heating lamp, power: 1600W). 4. Dehumidification function: power 420W. (Upper humidity limit: 10-60%RH; Lower humidity limit: 10-60%RH). 5. Total power includes: conjugate collection device power 3352W and collection roller device power 1842W. | |

6. Syringe pump. Injection speed: 0.001-20mm/min. Syringe allowable needle volume: 10ml-50ml. The standard syringe volume of the injection pump is 20ml. The stroke setting range is 0.01-90 mm. Weight: 2Kg. | ||

7. Collection roller. Spindle speed: 500-3800rpm, the minimum increment is 100 rpm. Swing speed: 5-100 mm/s, the minimum increment is 5 mm/s, Swing range: 100-200 mm. Roller specification: φ80×200 mm. Weight: 5Kg. |  | |

8. Conjugate collection device: The adjustable range of syringe needle distance is 20-60cm; Conjugate shaft speed: 500-3000rpm; Conjugate collection roller speed: 1-500rpm; Effective lifting stroke: 180mm (speed 0.1-5mm/s). |  | |

9. Product specifications: ·Size: 1100mmX1100mmX1200mm. ·Weight: 100Kg. |  | |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics:

About us:

Shenyang Kejing keeps "practical, dedicated, hard-working, teamwork, credible, innovative, responsible, customer-first, high-quality products, advanced services" as the motto, dedicated to providing brilliant products and services to customers home and abroad.