5-Position Dip Coater With Speed And Heating Chamber

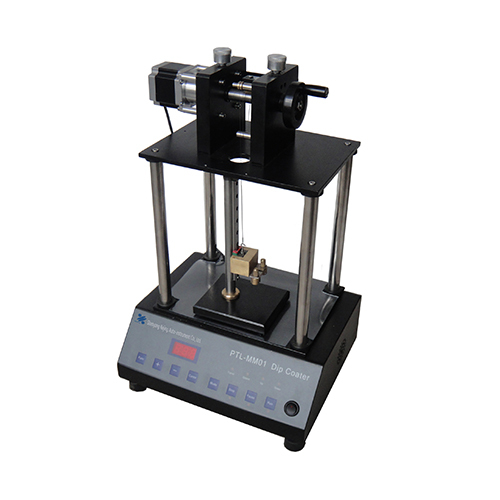

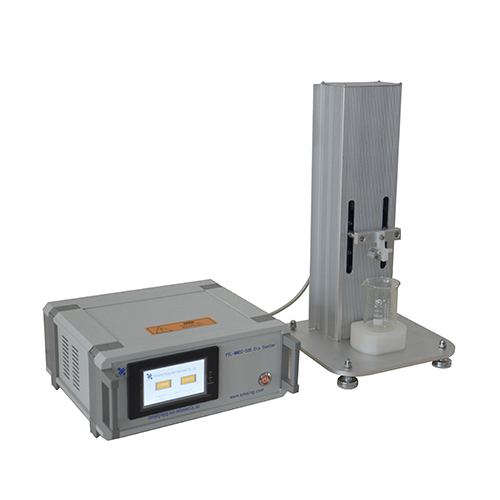

PTL-OV5P Automatic 5-Position Thermostatic Dip Coater is used for multi-layer (up to 5 layers) dipping and coating of the same sample in different liquid coating materials. The machine is equipped with a pulling wire to fix up to two identical samples for dipping and coating at the same time. After one coating, manually turn the charging beaker to make the sample enter the next coating process. This machine is equipped with a thermostatic oven.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Main Features

1. A color touch screen is adopted to set and adjust pulling speed, declining speed and dwell time according to actual needs.

2. The whole process of dipping and coating is carried out at a constant temperature, which is conducive for the solidification of the film.

3. After coating with one liquid coating material, it will automatically transfer to the next process.

4. The technology of suspended motor is used for shock absorption.

5. A high-precision stepper motor is adopted.

6. The 5-position liquid carrier plate rotates automatically according to the program.

Technical Parameters

Product Name | PTL-OV5P Automatic 5-Position Thermostatic Dip Coater |

Product Model | PTL-OV5P |

Installation Conditions | This equipment is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: N/A 2. Electricity: AC220V 50Hz, must have good grounding 3. gas: N/A 4. Workbench: size 800mm×600mm×700mm, bearing more than 200kg 5. Ventilation device: no need |

Main Parameters (Specification) | 1. External power supply of the main part of the equipment: AC220V, 50Hz, 3A, 850W 2. Pulling speed: 1mm/min-200mm/min 3. Temperature: RT-100℃ 4. Loading beaker: Φ60mm, 150ml 5. Dipping and drying time setting: 1-999s 6. Pulling times of each station/position: 1-20 times 7. Effective dipping length: 60mm 8. Sample size: 75mm×25mm×2.5mm 9. The ambient temperature is 5~40℃, the relative humidity is not more than 85%RH, and there is no strong earthquake source or corrosive gas around the equipment. Thermostatic oven technical parameters: 1. Temperature range: room temperature +5~100℃ 2. Temperature fluctuation: ±1.5℃ 3. Dimension: 460mm×510mm×695mm |

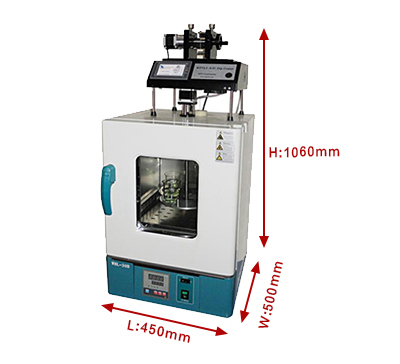

Product Dimension and Weight | Dimension: 450mm×500mm×1060mm weight: 45kg

|

Standard Accessories | 1. Coating Fixture: 1 set 2. Beaker (150ml): 5 pcs 3. Pulling Wire: 3 pcs |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics