- Company News

- Industry News

- Video

- Cutting and Dicing Saw

-

Grinding and Polishing Machine

- Precision Grinding and Polishing Machine

- Automatic Pressure Grinding and Polishing Machine

- Automatic Metallographic Grinding and Polishing System

- Vibratory Polishing Machine

- Auxiliary Device for Grinding and Polishing

- Grinding and Polishing Machine Accessories

- Grinding and Polishing Machine Consumables

- Electrolytic Polishing and Etching Machine

- Testing and Analysis Instruments

- Film Coating Machine

- Melting System

- Plasma Cleaner

- Lab Mill and Mixer

- Lab Press

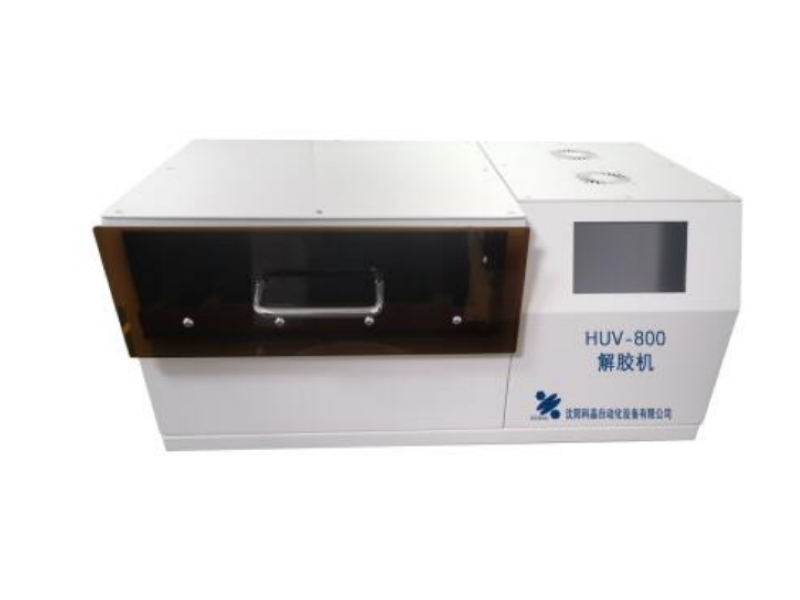

What Is UV LED Debonding Machine?

UV LED debonding machine is a common equipment in the curing industry, which has many unique features and advantages. In this article, we will explore the application areas of UVLED debonding machine and its outstanding features.

What is UV LED debonding machine?

UV LED debonding machine is a kind of equipment based on ultraviolet curing technology, which is specially designed for UV film debonding of precision materials such as wafer chips. It uses LED ultraviolet debonding lamp with cold light source to accurately and efficiently complete the curing and debonding process of UV cutting film tape.

Wide application of UV LED debonding machine:

UV LED debonding machine plays a key role in many industries, especially in the wafer packaging industry.

Semiconductor material processing: Ceramic cutting, glass processing, LED integrated chip production, etc.

Optical component processing: UV film debonding of optical lens.

Electronic equipment manufacturing: Curing treatment of circuit boards and other precision electronic components.

Technical features and advantages of UV film debonding LED curing machine:

Compared with traditional mercury lamp curing equipment, UV film debonding LED curing machine has the following significant features:

1. Equipped with an intelligent control panel, which can freely adjust the irradiation time and power to meet the processing needs of different materials.

2. The service life of LED light sources is more than 10 times longer than traditional mercury lamps, reaching an average of 20,000 hours, which greatly reduces maintenance and replacement costs.

3. Adopting a closed module design, there is no ultraviolet side leakage and no damage to the operator; at the same time, the LED cold light source has no thermal radiation and does not damage heat-sensitive materials, which meets environmental protection requirements.

4. Low energy consumption, the power consumption is 10% of the traditional mercury lamp curing machine, which can save 90% of electricity.

The emergence of UV film debonding LED curing machine not only solves the problem of possible damage to materials caused by traditional equipment under high-temperature operation, but also achieves higher product quality stability through low-temperature, uniform UV light irradiation. In addition, its long-life design and environmentally friendly features provide users with a more cost-effective production method.

As the global manufacturing industry moves towards environmental protection and efficient production, UV film debonding LED curing machine will continue to play an important role in semiconductor, optical processing and other industries, promoting the upgrading and innovation of industry standards. If you are looking for a high-performance and environmentally friendly degumming equipment, the UV LED degumming machine is undoubtedly a choice you cannot miss.