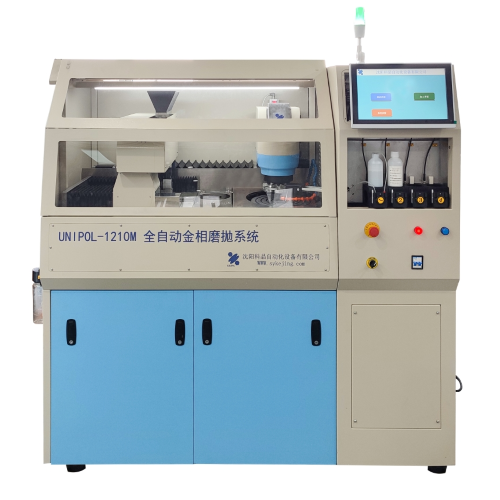

Do You Know How the UNIPOL-1210M Fully Automatic Metallographic Grinding and Polishing System Reduces the Operator Burden?

2025-01-07 16:30In materials science research, the efficiency and accuracy of the metallographic sample preparation process directly affect the reliability of experimental results. In order to meet the needs of scientific research institutions and industrial laboratories for automation, precision and consistency, we have developed a device called "UNIPOL-1210M fully automatic metallographic grinding and polishing system", which not only provides a highly integrated sample preparation solution, but also can cover a series of full-process automated operations such as mounting, grinding, polishing and cleaning. Let's take a look at how the automatic grinding and polishing machine performs at work!

The automatic metallographic grinding and polishing machine closely links the automatic mounting, grinding and polishing and cleaning units together, realizing a fully automated sample preparation process from mounting-sampling-grinding-cleaning-polishing-cleaning. Through one-button start and touch screen operation, users can accurately control the parameters of each step, including mounting pressure, temperature, time, grinding and polishing speed and cleaning intensity. In addition, the automatic grinding and polishing machine supports parameter setting archiving to unify the consistency of each operation. The entire process does not require manual intervention, which not only significantly saves labor costs, but also effectively avoids human errors.

At the same time, we fully considered the convenience of user operation during design and adopted the following design ideas:

1. Touch operation interface: Real-time display of each process status, support for programmable software system and program storage.

2. Material database: Built-in multiple material parameter settings to ensure consistency in the production process.

The automatic metallographic grinding and polishing machine not only realizes the automation of the entire process, but also improves the sample preparation efficiency of the laboratory. As a fully automatic metallographic grinding and polishing system in the laboratory, it greatly reduces the burden on the staff in operation.In addition, we also have our own professional laboratory. You are welcome to visit or use the laboratory for sample preparation at any time. We look forward to your arrival!