NanoFiber Electrospinning System With High Voltage

Electrospinning is a simple and effective process, with the action of a high-voltage electric field, for spinning polymer solutions or melts into fine fibers with dimensions ranging from micrometers to nanometers, namely polymer jet electrospinning.

It can be used for preparation of biopolymers, commodity polymers, and prepolymer nanofibers; preparation of polymer blend nanofibers; preparation of surfaces or films with nanopores, nanoparticles, and nanobeads.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Main Features

1. Equipped with positive and negative high voltage, the voltage is continuously adjustable to ensure accurate voltage

2. The whole machine is made of anti-corrosive materials

3. Capable of preparing stable and uniform nanofiber membrane

4. There is no additional electric field interference inside the chassis, the spinning voltage is stable, and there is no wire.

5. A variety of nozzles and yarn collectors can be optional.

6. Optional multi-channel injection pump (single-channel, dual-channel, five-channel, etc.)

7. The liquid injection pump is specially designed for electrospinning, and the thrust is 3 times that of ordinary medical injection pump, which can be used for high viscosity liquids. High pressure working environment, suitable for transferring various liquids for electrospinning.

Technical Parameters

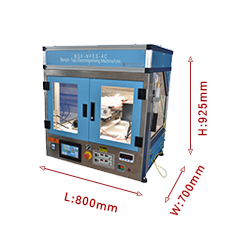

Product Model | MSK-NFES-4C Bench-Top Electrospinning Machine/Unit | |

Product Features | 1. Equipped with positive and negative high voltage, the voltage is continuously adjustable to ensure accurate voltage 2. The whole machine is made of anti-corrosive materials 3. Capable of preparing stable and uniform nanofiber membrane 4. There is no additional electric field interference inside the chassis, the spinning voltage is stable, and there is no wire. 5. A variety of nozzles and yarn collectors can be optional. 6. Optional multi-channel injection pump (single-channel, dual-channel, five-channel, etc.) 7. The liquid injection pump is specially designed for electrospinning, and the thrust is 3 times that of ordinary medical injection pump, which can be used for high viscosity liquids. High pressure working environment, suitable for transferring various liquids for electrospinning. | |

Technical Parameters (Specification)

| 1. Power supply: 220V 50Hz 2. Total power: 2350W 3. High voltage power supply: positive high voltage+50kV, negative high voltage-20kV 4. Temperature control range: RT-50℃ 5. Dehumidification function: power 280W | |

4. syringe pump * Injection speed: 0.0001-0.9mm/s * Maximum allowable diameter of syringe: φ50mm * Standard syringe volume of injection pump: 20ml, optional 30ml and 50ml * Setting range of travel distance: 0.01-90mm * Weight: 2kg |

| |

Main parameters of liquid injection pump mobile slide 1. X-axis effective mobile travel distance: 100mm 2. Y-axis effective mobile travel distance: 220mm 3. The inclination of the liquid injection pump can be manually adjusted within a certain range. |

| |

5. Collection roller * Spindle speed: 400-4400rpm with a minimum increment of 30 rpm * Roller size: φ80×200mm |

| |

6. Collection platform (optional) Manual control: X-axis speed: 1-10mm/s Y-axis speed: 1-10mm/s Automatic control: X-axis speed: 1-20mm/s Y-axis speed: 1-10mm/s Sample size: length 1-180mm, width 1-180mm Space between layers: 0.1-100mm Weight: 10kg |  | |

Product Dimension and Weight | 1. Dimension: 800mm(L) ×700mm(W)×925mm(H) 2. Weight: 75kg

| |

cautions | 1. Make correct wiring before use. Read the instruction manual carefully. 2. Check and confirm that all wiring is correct before starting the device. 3. Turn on the lighting, temperature and exhaust switches on the control interface to confirm whether the lighting, heating and exhaust systems in the box work properly. 4. Connection and inspection of high voltage power supply. Before use, check whether the high-voltage output line and the nozzle are well connected, and whether the polarity is correct; when using the voltage adjustment button for the first time, turn it counterclockwise to the end, turn on the power supply and turn the adjustment button clockwise to increase the voltage. At this time, the display shows voltage and current value respectively. 5. When debugging of the syringe pump, use touch screen to debug whether the syringe pump is running normally. 6. When loading electrospinning solution, use syringe to fill the solution manually. 7. During electrospinning operation, it is strictly forbidden to open the door of the box without cutting off high-voltage DC power supply, or touch the metal needle of the electrospinning spinneret with hands, which may cause damage to human body by high-voltage DC power supply. When high-voltage DC power supply is not cut off due to the needs of electrospinning, the metal needle must be moved with an insulator material. 8. When the electrospinning machine works abnormally, high-voltage DC power supply should be turned off immediately, and should be checked by professional and technical personnel. Normal electrospinning can only be carried out after troubleshooting. 9. When adjusting voltage, slowly adjust it clockwise to the required voltage value. When turning off the power supply, turn the power supply voltage (rotary) button counterclockwise to the end (to the 0 position) and turn it off. 10. When the cabinet door is opened, high-voltage power supply and other equipment should stop working. When replacing the electrospinning liquid for the injection pump in the electrospinning box, high-voltage DC power supply must be turned off first. 11. Before sampling, the discharge rod should be in contact with the collector to impose accumulated electric charge onto the sample. Discharge to the ground to ensure personal safety. 12. This equipment is not suitable for electrospinning strong corrosive solution. | |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics