- Home

- >

- Products

- >

- Guide Wheel

- >

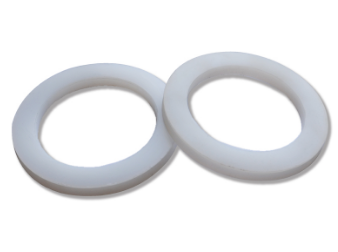

Guide Wheel

1. The guide roller wheel effectively guides the diamond wire to move in a fixed direction, ensuring cutting accuracy.

2. By cooperating with the tension wheel, the guide roller wheel can optimize the tension distribution of the diamond wire and reduce wire loss, thereby speeding up the cutting speed and improving work efficiency.

3. The guide roller wheel is made of high-quality materials, which is wear-resistant and corrosion-resistant, and prolongs its service life.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 100 sets

- Information

Introduction of guide roller wheel:

The bearing roller guide wheels we provide are lightweight, which can reduce the overall load of the equipment and help improve the efficiency of the equipment. The plastic guide wheels have excellent corrosion resistance and are not easily affected by chemicals, moisture or oxidation, making them suitable for use in harsh environments. The bearing roller guide wheels have a low friction coefficient when in contact with other parts during operation, which can reduce friction losses, thereby extending the service life and improving operational stability and reducing maintenance costs. High-performance bearing roller guide wheels have good wear resistance and can maintain their shape and function for a long time.

Advantages of guide roller wheel:

The guide roller wheel is suitable for different types of STX series diamond wire cutting machines and can be flexibly applied to various sample cutting scenarios, including metal, glass, ceramics and other materials.

The design of the guide roller wheel takes into account the stability during the cutting process, ensuring that the diamond wire will not deviate or break under high-speed cutting, ensuring the safety of the operator.

The guide roller wheel helps to improve equipment performance while reducing the cost of use.

Precautions for use:

When using bearing roller guide wheels, avoid overloading to avoid damage or poor shock absorption. Regularly check the appearance of the guide roller wheel for wear and replace damaged parts in time. These precautions can ensure the stability and service life of the guide wheel, while ensuring the stability and processing accuracy of the machine, reducing noise and impact on the surrounding environment.

Logistics:

About us:

We are committed to providing customers with an excellent service experience, especially in logistics and packaging. Our experienced logistics team is familiar with customs regulations around the world and can handle various international transportation needs quickly and efficiently. Whether it is sea, air or land transportation, we can ensure that the products arrive at their destination on time and safely.

In terms of product packaging, we use high-quality materials and strict standards to ensure that the products are not damaged during transportation. Our packaging team carefully checks each product to ensure that it meets export standards and customizes the packaging according to the characteristics of the product to minimize the risks during transportation.