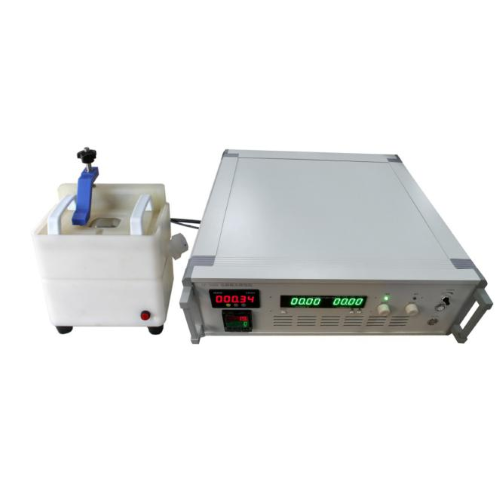

Electrolytic Polishing And Corrosion Instrument

1. The voltage and current of the electrolytic corrosion polishing machine can be customized (optional).

2. The voltage and current of the electrolytic corrosion polishing machine have coarse and fine adjustment switching functions, which can accurately and stably set the voltage and current values (optional).

3. The voltage and current of the electrolytic corrosion polishing machine can be adjusted and displayed with two decimal places of accuracy (optional).

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Introduction of electrolytic corrosion polishing machine:

The EP-6100 electrolytic corrosion polishing machine uses the principle of electrochemistry to prepare metallographic samples. Electrolytic corrosion polishing machine can be used for both polishing and corrosion of metallographic samples. It has the advantages of fast sample preparation, good repeatability, and no deformation layer caused by mechanical processing. Electrolytic corrosion polishing machine is an ideal equipment for preparing metallographic samples of non-ferrous metal samples, steel, especially stainless steel.

Advantages of electrolytic polishing corrosion instrument:

1. The voltage and current range of electrolytic polishing corrosion instrument is large, which can meet the polishing and corrosion of various materials at the same time.

2. Laboratory electrolytic polishing corrosion instrument can realize constant current and constant voltage working mode.

3. It can control the polishing/corrosion area of the sample, thereby ensuring the stability of the polishing/corrosion current of the sample.

4. Laboratory electrolytic polishing corrosion instrument can control the working temperature of the polishing/corrosion liquid.

5. Laboratory electrolytic polishing corrosion instrument can control the polishing/corrosion time.

6. The stirring device of laboratory electrolytic polishing corrosion instrument ensures that the polishing/corrosion medium is uniform and the sample surface environment is consistent.

7. The heating device of laboratory electrolytic polishing corrosion instrument can select the required polishing and corrosion temperature.

Technical parameters of electrolytic corrosion polishing machine:

| Product name | EP-6100 Electrolytic Polishing and Corrosion Instrument |

| Product model | EP-6100 |

| Main parameters | 1. Working voltage: AC220V, 50Hz. 2. Output voltage: 0-100V, digital display, voltage can be preset. 3. Output current: 0-6A, digital display, current can be preset, with overload protection. 4. Total power: 900W. 5. Working time: 1 second-99 minutes and 59 seconds, digital display, time can be set; after reaching the set time, the buzzer reminds. 6. Temperature range: Room temperature-100 degrees Celsius. 7. Control power supply size: 290×375×120mm. 8. Magnetic stirrer size: 240×200×132mm. 9. Weight: 15.5Kg.

|

Standard accessories:

| NO. | Name | Qty | Picture |

| 1 | Power supply | 1 unit | -- |

| 2 | Standard polishing/corrosion components (including cooling coils, cathodes, etc., sample cover: controls the sample polishing area, one for each of 10, 20, and 30 mm diameter) | 1 set | -- |

| 3 | Simple polishing/corrosion components (iron stand, anode support plate, anode clamp, cathode, etc.) | 1 set | -- |

| 4 | Stirrer and heating control unit | 1 set | -- |

| 5 | Container | 2 units | -- |

FAQ:

1.What are the features of the time control function?

It supports time settings from 1 second to 99 minutes and 59 seconds, and a buzzer reminds you when the run is finished, which facilitates accurate management of the experiment.

2.Is the equipment's shipping packaging safe enough?

Yes, it uses shockproof and moisture-proof packaging to ensure the equipment is safe and intact during transportation.

About us:

Shenyang Kejing's products are widely recognized in the global market and cover a variety of application fields. We have a professional technical team, relying on our profound industry background and innovation capabilities to ensure high precision and high reliability of products in design and manufacturing. We look forward to working with you to create a better future and become your preferred partner in the field of precision instruments.