Benchtop Automatic Ultrasonic Spray Pyrolysis Machine

1.Automatic ultrasonic spray pyrolysis machine adopts plc program control, and the touch screen is easy to operate.

2.Automatic ultrasonic spray pyrolysis machine adopts synchronous pulley connected to linear guide rail slideway structure, high speed and low noise.

3.Automatic ultrasonic spray pyrolysis machine adopts sheet metal frame structure, beautiful appearance.

4.Automatic ultrasonic spray pyrolysis machine can replace different nozzles and adjust the height to achieve the best effect on the atomization surface.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of ultrasonic spray pyrolysis coating machine:

MSK-USP-04CT ultrasonic spray pyrolysis coating machine uses a stepper motor and a microprocessor to control the volumetric pump, thereby ensuring the accurate delivery of solvents by the infusion device and the continuity of the ultrasonic spray process. An ultrasonic atomizer is used to prepare thin micro-nano coatings, and a stepper motor controls the sprayer to move in the x-axis and y-axis directions, and the moving speed can be adjusted within a certain range to ensure the uniformity of the coating on the surface of the substrate after spraying. The ultrasonic spray pyrolysis coating machine controls the substrate temperature through a heating platform to accelerate the drying speed of the film. The heating temperature of the heating platform can be as high as 300℃, which can basically meet the needs of most experiments within this temperature range.

Advantages of automatic ultrasonic spray pyrolysis machine:

Automatic ultrasonic spray pyrolysis machine adopts spray pyrolysis film making method, which is to spray the solution into atomized form onto a heated substrate, and then obtain the desired material structure on the substrate. This material preparation method is particularly suitable for depositing oxides, and has a long history of application in the preparation of transparent electrodes. Now this method is widely used in the preparation of perovskite solar cells.

Technical parameters of desktop automatic ultrasonic spray pyrolysis coater:

| Product name | MSK-USP-04CT Ultrasonic Spray Pyrolysis Coating Machine | |

| Product model | MSK-USP-04CT | |

| Product features | 1.PLC program control, easy touch screen operation. 2.Desktop automatic ultrasonic spray pyrolysis coater uses a synchronous pulley connected to a linear guide rail slideway structure, high speed and low noise. 3.Desktop automatic ultrasonic spray pyrolysis coater uses a sheet metal frame structure with beautiful appearance. 4.Desktop automatic ultrasonic spray pyrolysis coater can replace different nozzles and adjust the height to achieve the best effect on the atomization surface. 5.The nozzle is equipped with pneumatic assistance, which can effectively control the atomized solution particles to deposit in the specified area. | |

| Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 5-45℃. 2. There is no strong vibration source and corrosive gas around the equipment, and the surrounding space is not less than 200mm. 3. Water source: no requirement. 4. Power supply: single phase: AC220V 50Hz national standard three-pole socket 16A must have good grounding. 5. Gas source: compressed gas (air compressor) > 0.4Mpa. 6. Workbench: recommended size: 1000x800x550mm, load-bearing 150Kg or more solid platform. 7. Ventilation device: The equipment needs to be connected to the exhaust pipe. | |

| Main parameters | 1. Host power supply port: AC220V, 50Hz, 16A. 2. Host total power: 2.8KW (excluding air compressor). 3. X-axis travel: 1-300mm. 4. Y-axis travel: 1-220mm. 5. X-axis speed range: Manual operation control: 10-300mm/s. Automatic operation control: 10-600mm/s. 6. Y-axis speed range: Manual operation control: 10-300mm/s. Automatic operation control: 10-600mm/s. 7. Layer spacing: 1-100mm. 8. Z-axis manual maximum adjustment: 90mm. 9. Atomizing nozzle: CSA40-1 mushroom head: wider spray diameter - 40mm 1. CSA40-2 cylindrical tip: narrower spray diameter -20mm 1 pc. 10. Ultrasonic nozzle frequency: 40KHz±10%: 11. Ultrasonic maximum power: 200W. 12. Particle size: 10-20um. 13. Flow rate: 0.6pl-4ml/min. 14. Viscosity: ≤100cps. 15. Solid content: ≤10%. 16. Exhaust port: Φ75mm. 17. Host operation control mode: 7-inch touch screen + AT intelligent temperature control meter. | |

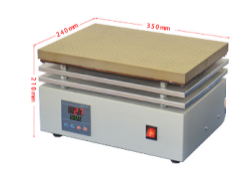

18. Cast copper heating plate size: 350×240mm. 19. Heating range: room temperature-300℃. 20. Heating power: 2.5KW. |  | |

21. Syringe pump dimensions: 250×65×50 mm. 22. Injection speed: 0.001-20 mm/min. 23. Fine-tuning speed: 0.001-10 mm/min. 24. Syringe diameter: 0.04-30 mm. 25. Standard needle volume: 20ml. 26. Stroke setting range: 0.01-90 mm. 27. Operation control mode: 4.3-inch touch screen independent setting (linked with the host). 28. Pump power: ≤50W. 29. Pump power supply port: DC24V (standard "power adapter" IN: AC100-240V 50/60Hz OUT: DC24V 3.75A). |  | |

30. Product specifications: Dimensions: 700×620×800mm. Total weight: 120Kg. |  | |

Notes: 1. The equipment is powered by the domestic standard AC220V 50Hz power supply. The actual power supply is subject to the parameters on the rear label of the product. 2. The injection pump is powered by an independent power adapter, and the parameters are set independently. It is linked with the host to start "Run". | ||

Optional accessories for ultrasonic spray pyrolysis coating machine:

| NO. | Name | Function | picture |

| 1 | Catheter coating | (Optional) |  |

About us:

We not only cooperate with many famous domestic universities, such as Tsinghua University, Peking University, Fudan University, etc., but also cooperate with many foreign universities, such as Royal Melbourne Institute of Technology, etc. The reason why these schools cooperate with us is not only because we can provide them with high-performance equipment, but also because we are more in line with their teaching philosophy.